How much the tools cost

I get the occasional YouTube comment belittling my projects because I used

"$100,000 worth of tools" to build them. But that is far from the truth.

My tools cost much less than that. So I thought I'd do a post about what

my tools cost.

I get the occasional YouTube comment belittling my projects because I used

"$100,000 worth of tools" to build them. But that is far from the truth.

My tools cost much less than that. So I thought I'd do a post about what

my tools cost.

This is my delta hybrid table saw. It was marked at $900 Canadian dollars, plus sales tax. Sales tax is like the value added tax (VAT) in Europe, but it's 13% added to the sticker price at checkout, whereas VAT is already included in the sticker price.

The saw had a $150 rebate and a $200 rebate on it, so it ended up costing me $676 after taxes. The cost was a big part of the reason I bought it. It needed a bit of work, but it's a decent table saw. Not as good as a cabinet table saw, but it does the job.

I think I paid around $150+tax for this drill press,

on sale for 50% off at Canadian Tire back in 1999.

I think I paid around $150+tax for this drill press,

on sale for 50% off at Canadian Tire back in 1999.

My main annoyance with this drill press is changing the speeds. It has 18 speeds, but I really only use two speeds, and to switch between them I have to move both belts. Quite annoying. If it didn't have this intermediate pulley for the extra speeds, it would be much easier to deal with!

Before this one, I used a small benchtop drill press I bought for $20 at a yard sale. The small benchtop drill press is now in my big workshop in the country, where I still use it. You can see it in use here.

Behind the drill press are my drill bits and all my

frequently used hand tools.

Behind the drill press are my drill bits and all my

frequently used hand tools.

I have a set of large Forstner bits, up to 2 1/4". That cost $70+tax. The gray drill index to the right of the drill press I bought over 20 years ago, no idea how much it cost. The brad point drill set above that one I think cost around $30+tax.

The blue handled chisels are my Marples chisels. Funny thing, I think on a podcast, Marc Spagnuolo (The Wood Whisperer) referred to his Marples chisels disparagingly (as in, not his "good" chisels). My Marples chisels are my good chisels! I bought them in 1995.

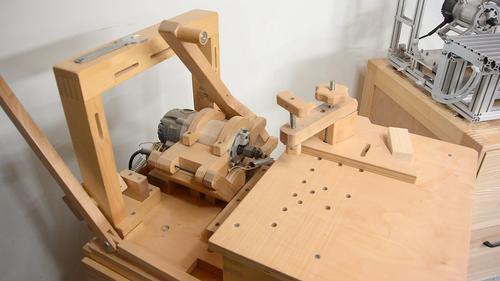

I didn't spend much money building this bandsaw.

Maybe around $60 for the shafts and bearings, I don't remember.

Also some bicycle inner tubes for tires (I think around $5 each),

a V-belt for $10 and various screws and such.

I didn't spend much money building this bandsaw.

Maybe around $60 for the shafts and bearings, I don't remember.

Also some bicycle inner tubes for tires (I think around $5 each),

a V-belt for $10 and various screws and such.

My old 14" bandsaw cost, I think, around $550+tax. I bought it in 1996 at a wood show. It's now at my shop in the country (see it here).

Building a bandsaw can be a cheap way to get a bandsaw if you are mechanically

inclined, and already have some of the stuff. The most expensive part to buy is the

motor. If you have to buy that, it can easily double your costs. It might be

cheaper to buy a dust collector

and take the motor out of it than to buy the motor on its own.

Building a bandsaw can be a cheap way to get a bandsaw if you are mechanically

inclined, and already have some of the stuff. The most expensive part to buy is the

motor. If you have to buy that, it can easily double your costs. It might be

cheaper to buy a dust collector

and take the motor out of it than to buy the motor on its own.

My homemade 12" jointer

is my most expensive homemade machine.

I paid $200+tax for a new planer for the cutter head and motor, $70 for the metal on top,

and $70 for a 5'x5' sheet of baltic birch, most of which I used up on the jointer.

Also some 2x6's. The rest of the wood was recycled lumber.

All in all, I probably spent $400 building it.

My homemade 12" jointer

is my most expensive homemade machine.

I paid $200+tax for a new planer for the cutter head and motor, $70 for the metal on top,

and $70 for a 5'x5' sheet of baltic birch, most of which I used up on the jointer.

Also some 2x6's. The rest of the wood was recycled lumber.

All in all, I probably spent $400 building it.

I think my old 6" jointer cost around $700, back in 1996. And at that price, that is the most expensive piece of woodworking equipment I ever bought. My brother bought a used 6" jointer back around 2005 for $250.

If you buy a jointer, get a 6" jointer made of cast iron. Wider would be better, but anything wider will cost twice as much, and anything less than 6" is generally junk. The tables on small combination jointer/planers are usually not rigid enough.

I bought my thickness planer

for $200+tax at Canadian Tire, on sale. I bought it to

take apart for building the jointer, but trying it out, I realized it was a better machine

than the Delta planer I bought for $400 back around 1998. So I

took the Delta planer apart instead.

I bought my thickness planer

for $200+tax at Canadian Tire, on sale. I bought it to

take apart for building the jointer, but trying it out, I realized it was a better machine

than the Delta planer I bought for $400 back around 1998. So I

took the Delta planer apart instead.

I bought this 6x48" belt sander at a pawn shop back in 1996, for maybe around $70.

Or maybe it was over $100. Too long ago to remember.

I bought this 6x48" belt sander at a pawn shop back in 1996, for maybe around $70.

Or maybe it was over $100. Too long ago to remember.

It's actually a Shopsmith attachment, but with a stand and motor. It's not a very good belt sander. The belt tracking is iffy, and the belt tensioning mechanism hardly works. But it does the job. I certainly recommend getting a 6x48" belt sander. Just not this one.

Update 2016: Replaced this one with a homemade belt sander

My scrollsaw. This one I bought for $35 at a yard sale. The guy who had this one

also had a 9" bandsaw for sale for $30, which I paid him for. But I was on my bike,

so I came to pick it up by car an hour later. In the mean time, he sold

the bandsaw to someone else.

My scrollsaw. This one I bought for $35 at a yard sale. The guy who had this one

also had a 9" bandsaw for sale for $30, which I paid him for. But I was on my bike,

so I came to pick it up by car an hour later. In the mean time, he sold

the bandsaw to someone else.

Well, I was upset at that, but then I bought his scrollsaw instead. That whole experience actually led me to building my first homemade bandsaw.

Here's my lathe. People often assume I have no lathe

because I never use it. But actually, I do use it - to hold up my scrollsaw!

Here's my lathe. People often assume I have no lathe

because I never use it. But actually, I do use it - to hold up my scrollsaw!

Lathes are mostly useful for ornamental types of work, like bowls and candlesticks. I'm not into ornamental work and don't need a lot of wooden bowls, so I don't use the lathe much. I think the last time I used it was for some marble blocks.

I paid $70 for it in 1998 at a yard sale. It came with a big metal stand, which I didn't take home. It also came with a big 1.5 hp motor, which now powers my first homemade bandsaw. The motor I have on the lathe now is just 1/2 hp, plenty for a lathe.

Update 2016: I built a lathe.

The homemade one in many ways isn't as good as this one, but it's easier to drag out

the homemade one than to move the clutter off this one.

My big Startrite dust collector. I paid $70 for this one at a University of Waterloo

surplus sale in 1998. It's only 3/4 hp, but it sucks much better than the

1 hp dust collector I bought for

$150+tax at Busy Bee Tools in 2013.

It's hooked up to my table saw, and I also have an opening near my belt sander.

My big Startrite dust collector. I paid $70 for this one at a University of Waterloo

surplus sale in 1998. It's only 3/4 hp, but it sucks much better than the

1 hp dust collector I bought for

$150+tax at Busy Bee Tools in 2013.

It's hooked up to my table saw, and I also have an opening near my belt sander.

My homemade dust collector.

My homemade dust collector.

I paid $25 for a really crummy table saw just for the motor to use in this one. The ABS piping also cost a bit of money (maybe $20). The two ShopVac filters on the inside cost about $25 each (they weren't the cheapest ShopVac filters). But the most expensive part of this dust collector is the 20 feet (6 meters) of 2 1/2" hose that I bought at Lee Valley tools.

My first table saw. I paid $135 for it in 1996.

The fence on it had broken at some point and was welded together so crookedly that

I threw it in the garbage and made a wooden one. The arbour had a bit of wobble to it, but

a new arbour for $50 fixed that. It cut very clean after that. The cast iron table has a slight

upward bow to it, but that is surprisingly not a problem in terms of cutting precisely.

My first table saw. I paid $135 for it in 1996.

The fence on it had broken at some point and was welded together so crookedly that

I threw it in the garbage and made a wooden one. The arbour had a bit of wobble to it, but

a new arbour for $50 fixed that. It cut very clean after that. The cast iron table has a slight

upward bow to it, but that is surprisingly not a problem in terms of cutting precisely.

My metal pantorouter.

I got this one for free as part of a royalty deal with

Kuldeep, who makes these for sale.

This also helped me make some videos about it, which helps Kuldeep

sell them.

My metal pantorouter.

I got this one for free as part of a royalty deal with

Kuldeep, who makes these for sale.

This also helped me make some videos about it, which helps Kuldeep

sell them.

If you were to buy this machine, it would cost you probably around $1000 US. Not cheap, but it's not the sort of thing that gets mass produced by the million in China. If you compare it to a Leigh FMT jig, or a JDS multirouter, it's more capable than either and costs less.

But you don't need to spend $1000 to get a pantorouter.

You can build one out of wood, using my plans.

But you don't need to spend $1000 to get a pantorouter.

You can build one out of wood, using my plans.

My strip sander. This one was on sale for 60% off at Canadian Tire in 2011, costing

me $47+tax. That was cheap enough that I just went and bought one without thinking

too much about whether I really needed one.

My strip sander. This one was on sale for 60% off at Canadian Tire in 2011, costing

me $47+tax. That was cheap enough that I just went and bought one without thinking

too much about whether I really needed one.

It's a handy sander, though there are a few things I have found frustrating about it.

I realized at some point that roller skate wheels could be used as idler wheels for a

1" belt sander, and seeing 42"x1" sanding belts at Busy Bee Tools, I thought I'd try to

build one, just quick and dirty. But then I drew it up in CAD to work out a few things

ahead of time. I played with the CAD model for a day and it became increasingly

detailed. So I built this one,

and I put together a set of plans for sale for it.

But making a good plans package is an awful lot of work, which is why I don't

have a project for this week.

I realized at some point that roller skate wheels could be used as idler wheels for a

1" belt sander, and seeing 42"x1" sanding belts at Busy Bee Tools, I thought I'd try to

build one, just quick and dirty. But then I drew it up in CAD to work out a few things

ahead of time. I played with the CAD model for a day and it became increasingly

detailed. So I built this one,

and I put together a set of plans for sale for it.

But making a good plans package is an awful lot of work, which is why I don't

have a project for this week.

Woodworking machines last a long time, and there is a good used market. If you keep

your eyes open, you can get some good deals. And when you buy something, it's

probably good for the next 50 years. Compare that to the high replacement rate

of anything high tech. Keeping current with the latest smart phones or cameras

can cost you more than having a wood shop. And having a wood shop can also save

you money from time to time.

See also:

My old garage

My old garageworkshop (2007)

My big garage workshop (2014)

My big garage workshop (2014) Brain Pick with Bob

Brain Pick with BobClagett interview (2015)

To my Woodworking website.

Last tour of my base-

Last tour of my base-

John Heisz's visits my workshop

John Heisz's visits my workshop My dad's workshop

My dad's workshop Visitng John Heisz

Visitng John Heisz Showing the nephews

Showing the nephews