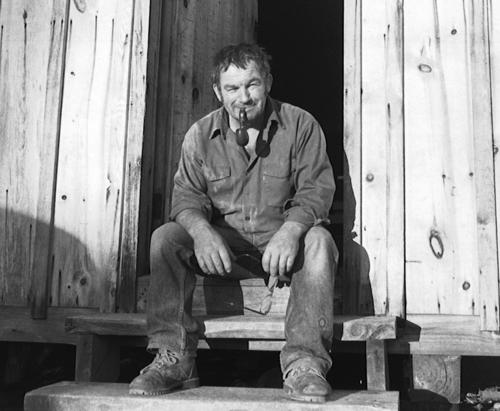

My dad passed away in 2012 and was buried in the local cemetery.

My dad passed away in 2012 and was buried in the local cemetery.

The soil was very rocky where they dug the grave, and among the soil they dug up was a rock that sort of looked like it could be a natural gravestone. We hadn't yet ordered a gravestone, so I had the idea to ask the backhoe operator, as he was filling the hole, to position that big rock as a temporary headstone.

Here's that stone, still dirty from having been dug out of the ground, and Markus installing

a temporary sign that he made.

Here's that stone, still dirty from having been dug out of the ground, and Markus installing

a temporary sign that he made.

My mom ended up liking that stone, and I'm sure my dad would have liked it too, but one family member was concerned that this might look too poor, and that a "proper" stone should be procured.

So I figured if I made a nice wooden grave marker, that would pre-empt the argument and make for a relatively unique and fitting monument. It would also be very fitting because my dad had made a living with cabinet making for the latter half of his life.

At left, my brother installing a temporary marker the day after the burial.

So I quickly drew it up in CAD to propose the idea

and work out the proportions.

So I quickly drew it up in CAD to propose the idea

and work out the proportions.

This is where Europe and North America differ substantially. Wooden grave markers are not that uncommon in Europe, because a grave site is leased and will eventually be dug up so that somebody else can be buried there. As such, a grave marker doesn't need to last forever. But here, burial plots are bought, and the idea is that the grave is there to stay. So a grave marker should last forever, which is why they are all made of stone. Graveyards are full of 100-year old graves. I figure this grave marker only needs to last 30 years. In 30 years, my mom will be 100 years old, so the whole issue will likely need revisiting before then.

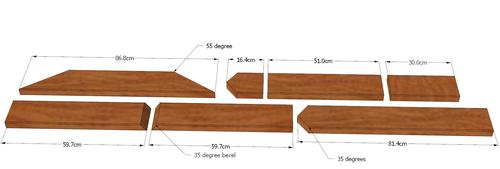

Once I was happy with how it looked in CAD, I rearranged all the parts flat, added dimensions,

and printed that out to work from in the shop. Two 2x6x8' cedar planks was all the wood

I would need.

Once I was happy with how it looked in CAD, I rearranged all the parts flat, added dimensions,

and printed that out to work from in the shop. Two 2x6x8' cedar planks was all the wood

I would need.

My router pantograph was perfect for carving the

inscription. But I've only made letter templates for it as needed, so I had to make a few extra

templates to be able to carve the inscription.

My router pantograph was perfect for carving the

inscription. But I've only made letter templates for it as needed, so I had to make a few extra

templates to be able to carve the inscription.

I started by cutting out the horizontal piece of the grave marker. I was still uncertain as to

how well the cedar would carve, so it was logical to start with that.

I started by cutting out the horizontal piece of the grave marker. I was still uncertain as to

how well the cedar would carve, so it was logical to start with that.

First name carved, and rearranging the blocks on my letter carrier to form "Wandel".

My letter carrier was not quite wide enough to put "Winfried Wandel" in it all at once,

but doing it as two parts allowed me to reuse some of the letter blocks.

First name carved, and rearranging the blocks on my letter carrier to form "Wandel".

My letter carrier was not quite wide enough to put "Winfried Wandel" in it all at once,

but doing it as two parts allowed me to reuse some of the letter blocks.

Moving the work piece to the left to carve the second name. Here I'm using my callipers to make sure

I have it positioned parallel and at the same distance from the letter carrier as before.

Moving the work piece to the left to carve the second name. Here I'm using my callipers to make sure

I have it positioned parallel and at the same distance from the letter carrier as before.

Work piece repositioned a second time to carve the dates.

Work piece repositioned a second time to carve the dates.

I wanted the letters to show up black, and I figured the best way to blacken them was to burn

the surface of the wood. That way, there would not be any risk of paint peeling off. So I used a

torch to burn the letters. I used the extra hot MPS gas, figuring that way I could char the surface

faster without burning the wood too deep. I also moistened the flat surface of the wood,

hoping that would cause it to burn less.

I wanted the letters to show up black, and I figured the best way to blacken them was to burn

the surface of the wood. That way, there would not be any risk of paint peeling off. So I used a

torch to burn the letters. I used the extra hot MPS gas, figuring that way I could char the surface

faster without burning the wood too deep. I also moistened the flat surface of the wood,

hoping that would cause it to burn less.

Letters burned. This didn't work out as well as I had hoped. The bottom of the letter grooves is

still unburnt, while the surface is thoroughly charred.

Letters burned. This didn't work out as well as I had hoped. The bottom of the letter grooves is

still unburnt, while the surface is thoroughly charred.

Now planing off the charred surface on my jointer, leaving just the blackened grooves.

Now planing off the charred surface on my jointer, leaving just the blackened grooves.

I wasn't very happy with the result. I had to plane fairly deep to get all the surface charring off. The edges were burned enough to make the letter look a little wobbly, yet the bottom of the grooves were still unburned.

As an aside, people always like the idea of "your father taught you well", and that knowledge is passed down that way. But there was never any explicit teaching. So much of what I "know" is stuff I thought of and tried out. The same goes for my dad, he was a completely self-taught woodworker. This is an example where trying something didn't quite work. I usually test an idea before trying it, and the method had worked adequately for a single groove that I milled and burned, but for the more intricate shapes, it didn't work as well.

Checking the layout on the floor, with the initial lettering. I had already cut out a second

horizontal piece at that time, but that left me short of material for the back, so I had to

go and buy more lumber.

Checking the layout on the floor, with the initial lettering. I had already cut out a second

horizontal piece at that time, but that left me short of material for the back, so I had to

go and buy more lumber.

With the pantograph still set up, carving the inscription again didn't take long.

With the pantograph still set up, carving the inscription again didn't take long.

I had some leftover scraps of sheet metal roofing from my

shed project, so I used some

of that to make a metal roof for the grave marker. Here I'm setting up to cut that to

size using a sheet metal cutting sawblade

in my table saw.

I had some leftover scraps of sheet metal roofing from my

shed project, so I used some

of that to make a metal roof for the grave marker. Here I'm setting up to cut that to

size using a sheet metal cutting sawblade

in my table saw.

I wasn't sure how well this would work. It was tempting to install the guard, but the kerf of the blade was too narrow for the saw's splitter. So I attached a board above the blade to hopefully catch some of the sparks

Making the rip cut. Cutting sheet metal like that is very loud! It worked ok,

though the edge was a bit rougher than I was hoping.

Making the rip cut. Cutting sheet metal like that is very loud! It worked ok,

though the edge was a bit rougher than I was hoping.

In the background, my initial lettering attempt cut out into a rectangular sign.

Afterwards, cutting the pieces to length. Again, a board set up as a sort-of guard.

Afterwards, cutting the pieces to length. Again, a board set up as a sort-of guard.

Now back to working on the rest of the marker. There weren't any complicated parts to this grave marker,

so work progressed very quickly.

Now back to working on the rest of the marker. There weren't any complicated parts to this grave marker,

so work progressed very quickly.

The two boards that form the roof of the marker, screwed together at the peak.

The two boards that form the roof of the marker, screwed together at the peak.

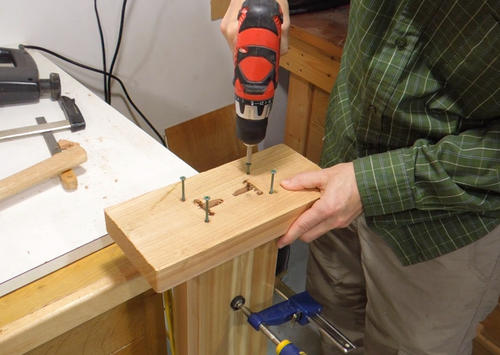

The main post is made of two pieces screwed together. I'm using the

green coated deck screws.

The main post is made of two pieces screwed together. I'm using the

green coated deck screws.

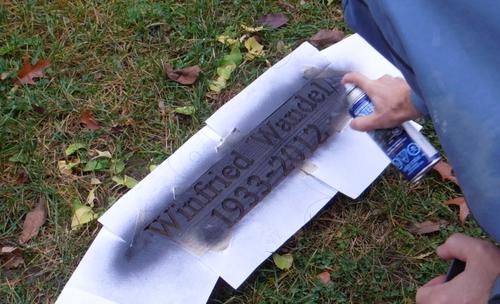

I wasn't sure about painting the letters and figured just the profile would be good, but mom said she'd prefer if the letters to be darker.

So I spray painted the lettering, using leftover paint from making my

dust photographing contraption, which was another article I was working on at the time.

So I spray painted the lettering, using leftover paint from making my

dust photographing contraption, which was another article I was working on at the time.

After letting the paint dry for a few days, I planed a thin layer off the surface, leaving just the

letters as black.

After letting the paint dry for a few days, I planed a thin layer off the surface, leaving just the

letters as black.

The hand plane was still perfectly sharp from filming my hand plane sharpening for barbarians video, despite repeatedly slamming it down on my cast iron table saw. I don't usually treat my planes like that, and I slammed it down quite a few times until I was happy with the video, but it didn't dull the blade any --- the plane left the surface smooth as silk.

For mounting the grave marker, I cut some T-shaped profiles between the layers of the post.

The idea was to drive two pieces of T-profile steel fence posts into the ground, then slip

the grave marker on top of that. That way, none of the wood from the grave marker ends up

in the ground. Wooden structures always rot where the wood enters the ground, and this

way, none of the grave marker would actually be in the ground.

For mounting the grave marker, I cut some T-shaped profiles between the layers of the post.

The idea was to drive two pieces of T-profile steel fence posts into the ground, then slip

the grave marker on top of that. That way, none of the wood from the grave marker ends up

in the ground. Wooden structures always rot where the wood enters the ground, and this

way, none of the grave marker would actually be in the ground.

The picture here shows me just finishing the flat part of the cut.

T-profiles finished. The deeper parts of the profiles were cut by making several side by side cuts

with my table saw.

T-profiles finished. The deeper parts of the profiles were cut by making several side by side cuts

with my table saw.

I also cut T-shaped holes into the base.

I also cut T-shaped holes into the base.

Screwing the base to the bottom of the post.

Screwing the base to the bottom of the post.

Finished grave marker, ready for installation. Although at this point, I still hadn't fully

screwed it together, just to make it easier to transport in pieces.

Finished grave marker, ready for installation. Although at this point, I still hadn't fully

screwed it together, just to make it easier to transport in pieces.

By the time I made my next trip to my mom, there was snow on the ground.

Here's pounding the T-shaped steel rods into the ground. I used two pieces of wood, both

with a slot cut into them to act as an alignment guide and keep the bars parallel

and correctly spaced as I pounded them in.

By the time I made my next trip to my mom, there was snow on the ground.

Here's pounding the T-shaped steel rods into the ground. I used two pieces of wood, both

with a slot cut into them to act as an alignment guide and keep the bars parallel

and correctly spaced as I pounded them in.

Except that the alignment guide didn't work as well as I had hoped. It looks straight enough in the picture, but by the time I pounded them in far enough, they went all crooked, deflected by rocks in the ground, and the fact that the end of the rods was slightly curved because I didn't start with a straight piece!

After several attempts, got them in the ground straight enough and parallel enough.

My initial hope had been to just slide the grave marker onto the ends of the rods, but that was kind

of hopeless at this point, especially with the ends of the rods slightly widened from repeated

pounding. So I assembled the post around the bars instead.

My initial hope had been to just slide the grave marker onto the ends of the rods, but that was kind

of hopeless at this point, especially with the ends of the rods slightly widened from repeated

pounding. So I assembled the post around the bars instead.

It looked kind of messy with all the dirty trampled snow all around it...

... but a month later, with fresh snow, it looked much better!

... but a month later, with fresh snow, it looked much better!

I like how the natural stone right behind the cross makes it look more substantial.

I screwed the earlier inscription attempt to the wall above the handtools

in my dad's shop. It's this corner that he worked in the most.

We don't have any plans for what to do with the shop, so for the forseeable future, the shop

will continue to be "Dad's workshop".

I screwed the earlier inscription attempt to the wall above the handtools

in my dad's shop. It's this corner that he worked in the most.

We don't have any plans for what to do with the shop, so for the forseeable future, the shop

will continue to be "Dad's workshop".

A relative from Germany said surely, the Christmas after my dad had passed would have been a sad one. Maybe we are a callous bunch, but it was one of the best Christmases in a long time. My sister came with her kids, which she had not been able to for some time, and it was good company. (see here and here). My dad had very much disengaged from activity around him in the last three years, so he had, in spirit, been absent for the previous years already. Twice before, in 2010 and summer of 2012 the family was asked to gather at the hospital, but in the end, he died suddenly but peacefully in his own home. Now that he has passed, it's easier to remember him for the man he once was, rather than the man he had become in his last few years.

I planted the grave marker in November of 2012. here's what it looks like, May 2014.

I was hoping with several layers of wood perservative that mom put on it, that it would keep the cedar colour longer. The wood has grayed, but it still looks fine.

And here in 2019, with my dad's granddaughter Harriet, born in 2015, a year after

the previous picture.

And here in 2019, with my dad's granddaughter Harriet, born in 2015, a year after

the previous picture.