Uli's router and saw table

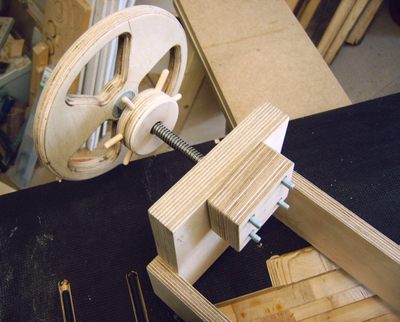

Router lift

Mounting a router to the bottom of a piece of plywood makes for a quick

and easy router table, it's also something I

do for a router table. But if the router one is using is a plunge router, adjusting

the depth of it can be quite inconvenient. Plus, the router may end up drifting a little

over time, as the springs and gravity both push the router down.

Uli Proppe has built a clever solution for this - a very simple router

table and router lift, based on a design by Guide Henn.

Mounting a router to the bottom of a piece of plywood makes for a quick

and easy router table, it's also something I

do for a router table. But if the router one is using is a plunge router, adjusting

the depth of it can be quite inconvenient. Plus, the router may end up drifting a little

over time, as the springs and gravity both push the router down.

Uli Proppe has built a clever solution for this - a very simple router

table and router lift, based on a design by Guide Henn.

He mounts his router using two steel shafts through the router's base, which are clamped

in place by a block of wood on one side, and the router lifting mechanism on the other side.

He mounts his router using two steel shafts through the router's base, which are clamped

in place by a block of wood on one side, and the router lifting mechanism on the other side.

The block that pushes against the router has four machine screws sticking out of it, which

push against the screws in the router's casing. This makes for a much better

reference than the router's plastic housing.

The block that pushes against the router has four machine screws sticking out of it, which

push against the screws in the router's casing. This makes for a much better

reference than the router's plastic housing.

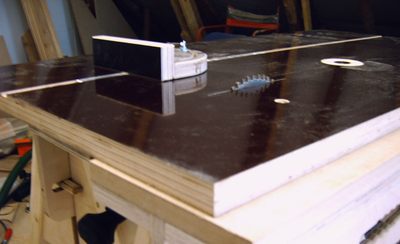

A nice fence finishes up the router table. Behind the router bit is a hinged flap

with a hole in it for connecting a vaccum to take away the wood chips.

A nice fence finishes up the router table. Behind the router bit is a hinged flap

with a hole in it for connecting a vaccum to take away the wood chips.

A home made miter gauge finishes it off. The miter gauge just runs in a slot

in the wood.

A home made miter gauge finishes it off. The miter gauge just runs in a slot

in the wood.

Update:

I have since built my own router lift and

router table

Circular saw mount

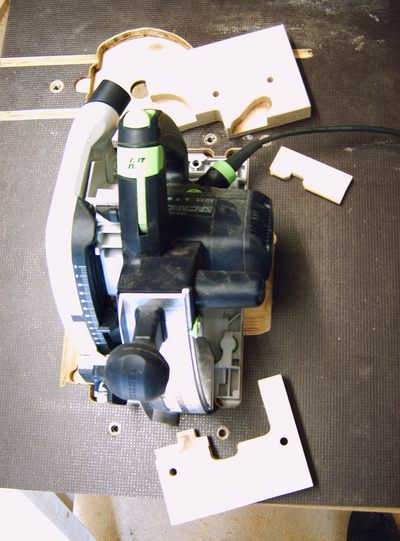

Uli doesn't have a table saw at this point, so he has another cavity at the bottom

of this piece of plywood for mounting his Festool rail saw.

Uli doesn't have a table saw at this point, so he has another cavity at the bottom

of this piece of plywood for mounting his Festool rail saw.

Proponents of rail saws say they can be used for many jobs one would normally use a table saw for. But why not use the saw as a table saw itself?

Festool also offers a table that the saw can be mounted under to use it as a table

saw, but like anything from Festool, it's costly. So Uli built his own, using

the same piece of plywood that he mounts the router under.

The saw is held in place by several blocks of wood, which are carved out to fit exactly

around the circular saw.

The saw is held in place by several blocks of wood, which are carved out to fit exactly

around the circular saw.

Typically when mounting a circular saw under a table to use as a table saw, making

adjustments to the saw is so awkward that it's more convenient to just flip the whole

thing over to do the adjustments.

Typically when mounting a circular saw under a table to use as a table saw, making

adjustments to the saw is so awkward that it's more convenient to just flip the whole

thing over to do the adjustments.

The Festool table for use with the rail saw comes with an accessory part for

easily setting the height of the cut and locking it in place when the saw is

on the bottom of the table. It's the part with the scale on it in this photo.

Uli bought just the parts needed for that as "spare parts" for the Festool table.

The equivalent part to this would have been very difficult to make out of wood,

and to buy the whole table would have been much more expensive.

The top of the saw, with the home made miter gauge to go with his table saw setup, though he's he

keeps saying he wishes he had a real miter gauge. Personally, I don't trust my miter

gauge either. Most of the time, I just use my

table saw sled.

The top of the saw, with the home made miter gauge to go with his table saw setup, though he's he

keeps saying he wishes he had a real miter gauge. Personally, I don't trust my miter

gauge either. Most of the time, I just use my

table saw sled.

When he built the table, he made the cut for the saw blade by plunge cutting from the side

that the saw was mounted, but had a slight error in alignment with the miter slot, and so

had to expand the holes just a little bit to accommodate. His suggestion is to plunge

cut the slot for the saw blade from the top instead. That way, it's easier to make sure

it's perfectly parallel to the miter slot.

Sawhorses

The whole assembly needs to rest on something, of course, and Uli has come up with some very sturdy knock-down sawhorses.

The saw horses lock together with pegs that are slid from the top section into the legs,

so that the whole sawhorse can be picked up without coming apart.

The saw horses lock together with pegs that are slid from the top section into the legs,

so that the whole sawhorse can be picked up without coming apart.

The tops of his saw horses are nice and wide, so that just one sawhorse is often enough.

There is also a sacrificial layer of MDF on the top. With sawhorses

this well made, it would be a shame to accidentally cut into the structure of the

sawhorse from time to time.

The tops of his saw horses are nice and wide, so that just one sawhorse is often enough.

There is also a sacrificial layer of MDF on the top. With sawhorses

this well made, it would be a shame to accidentally cut into the structure of the

sawhorse from time to time.

The sawhorses can handle over 200 kg, as has been tested when he built a massive set of stairs from beech with these sawhorses.

The sawhorses use no metal fasteners at all. The leg brackets are dadoed and pegged together, and the top glued. I do like that about German furniture makers - the aversion to just nailing things together. Nails are for cheap factory made furniture, but shouldn't be used for anything furniture grade. Although I have to admit, my own sawhorses are just nailed together

See also:

More woodgears.ca reader projects

Back to my Woodworking website

![]()

Builindg sawhorses

Builindg sawhorses How to build a

How to build a Beginning woodworking

Beginning woodworking A router table that's its own dust collector

A router table that's its own dust collector