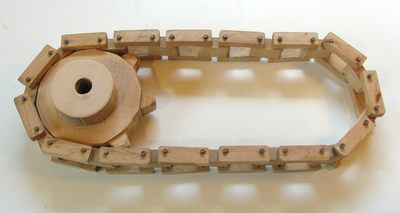

This little tank thread vehicle I built more or less as an experiment back in 1985. I had been experimenting with wooden chains, and so decided to try a block chain made out of maple as a tank thread.

Both the track and the sprockets are made out of maple. The track's 'pins' are actually

just a bunch of nails.

Both the track and the sprockets are made out of maple. The track's 'pins' are actually

just a bunch of nails.

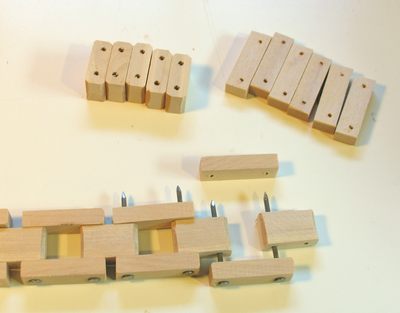

The center blocks of chains have a holes slightly larger than the nails, while

the outside tie pieces have holes slightly smaller than the nail, so that the nail

is held in by friction.

The center blocks of chains have a holes slightly larger than the nails, while

the outside tie pieces have holes slightly smaller than the nail, so that the nail

is held in by friction.

Once the nail is driven through the blocks, the sharp ends of the nails are cut off. Its really quite a simple process, although it does get a bit tedious to make for longer chains.

The surprising thing about a chain like that is its toughness. When I built this thing,

I didn't expect the chain to last, but I have had quite a lot of fun playing around

with this thing, and so far have not had the chain fail. The key I think is to use

a heavy close grained wood like maple to make it strong.

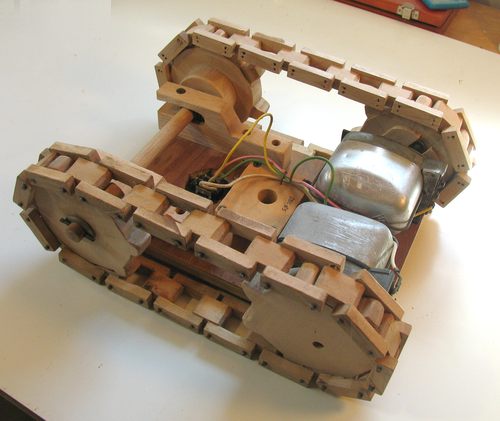

Propulsion for this vehicle is a pair of VW beetle windshield wiper motors. These are parts from

original VW beetles, which I pulled out of wrecked cars at the dump.

The drive sprockets are shaped to fit onto the crank, held on with just one screw.

Propulsion for this vehicle is a pair of VW beetle windshield wiper motors. These are parts from

original VW beetles, which I pulled out of wrecked cars at the dump.

The drive sprockets are shaped to fit onto the crank, held on with just one screw.

These exact motors are probably impossible to get nowadays,

so if you want to build something like this, you will have to find some other source of gear head

motors. I'm sure there are some models of wiper motors that could also be used.

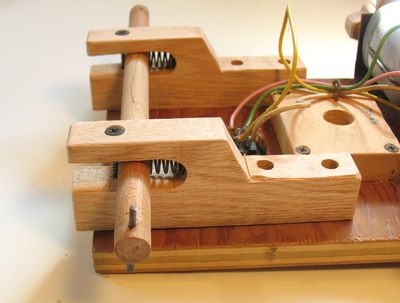

The idler pulleys for the other end of the chain simply run on a wooden shaft. I greased it a little

bit, although that wasn't really necessary. Note the springs in the blocks, which allow for a bit

of give but keep the chain taut.

The idler pulleys for the other end of the chain simply run on a wooden shaft. I greased it a little

bit, although that wasn't really necessary. Note the springs in the blocks, which allow for a bit

of give but keep the chain taut.

And here's the underside of the assembled vehicle. The motors are simply wired to a connector.

There's no battery or remote control electronics. I didn't care to mess with that sort of thing, and

being a high school student in Northern Ontario back in 1985, I certainly didn't have access

to that sort of electronics, or even the money for wireless remote control.

And here's the underside of the assembled vehicle. The motors are simply wired to a connector.

There's no battery or remote control electronics. I didn't care to mess with that sort of thing, and

being a high school student in Northern Ontario back in 1985, I certainly didn't have access

to that sort of electronics, or even the money for wireless remote control.

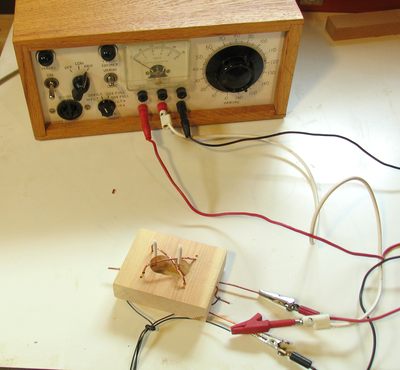

Instead of a remote control, the vehicle is tethered to a three conductor wire.

I run it off a center tapped power

supply. The ground of both motors connects to the center tap, and to move it in either direction, the

motor's other terminal is connected to the +12 or -12 volts taps on the power supply.

Instead of a remote control, the vehicle is tethered to a three conductor wire.

I run it off a center tapped power

supply. The ground of both motors connects to the center tap, and to move it in either direction, the

motor's other terminal is connected to the +12 or -12 volts taps on the power supply.

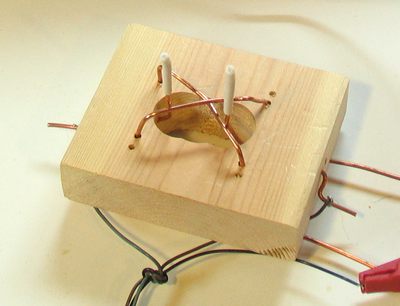

I didn't have a switch handy that would work well for this application, so just rigged something up very simple.

The crossing copper wires on the block are the +12 and -12 volts. Because one motor needs to run

in reverse and one forward to drive in a straight line, that means one motor connects to +12 and

the other to -12 volts when both sticks are pushed in the same direction. Hence the +12 and -12 volts

rails need to cross. Or the controls would be somewhat counter intuitive.

I didn't have a switch handy that would work well for this application, so just rigged something up very simple.

The crossing copper wires on the block are the +12 and -12 volts. Because one motor needs to run

in reverse and one forward to drive in a straight line, that means one motor connects to +12 and

the other to -12 volts when both sticks are pushed in the same direction. Hence the +12 and -12 volts

rails need to cross. Or the controls would be somewhat counter intuitive.

Having the controls work this way is good, because it means for straight line moves, the motors

are for the most part running in series off 24 volts. As such, the resistance of the long and

thin wire plays less of a part. The motors slow down noticeably when one is put in forward

and the other in reverse, because in that arrangement, they are on 12 volts in parallel, with current

for both having to go through the common conductor, so voltage drop from resistance is a much bigger factor.

Getting the wire caught in the tracks is a constant hazzard. A small mast

on top helps keep it clear of the tracks most of the time. It also helps to attach the other end of

the wire to something high. Otherwise, on backing up, one is likely to get entangled with the wire.

Getting the wire caught in the tracks is a constant hazzard. A small mast

on top helps keep it clear of the tracks most of the time. It also helps to attach the other end of

the wire to something high. Otherwise, on backing up, one is likely to get entangled with the wire.

The tether wire is not overly elegant, but - well - it just works, and it doesn't add to the weight of the vehicle. So really, I think its a pretty good solution.

And here's another video of it, just because its so much fun.

This one is of the vehicle driving around a pile of planer shavings. This works surprisingly

well, although the shavings do cause the tracks to come off once in a while.

Back to my Woodworking website

Plans for the wooden chains

Plans for the wooden chains Wooden chain powered by a wooden air engine

Wooden chain powered by a wooden air engine How DC motors work

How DC motors work Restoring the wiper motor powered forklift toy

Restoring the wiper motor powered forklift toy