Table extension

My dining table is not very large. So when I decided to have a larger dinner party, I had to rig up some sort of extension for this table.

For the top of my temporary extension I borrowed the top from this

wheely desk.

I made some brackets to screw it to the bottom of my table, and made one extra

supporting leg to hold it up.

For the top of my temporary extension I borrowed the top from this

wheely desk.

I made some brackets to screw it to the bottom of my table, and made one extra

supporting leg to hold it up.

To give the extension a bit more stability on its one supporting leg, I made the bottom

of the leg the shape of an upside-down "T". I used a bridle joint to connect the

leg to the cross member of the leg. I guess that sort of joint is more like an inside-out

mortise and tenon joint. I mostly used it because it leaves more of the material

for my upright intact.

To give the extension a bit more stability on its one supporting leg, I made the bottom

of the leg the shape of an upside-down "T". I used a bridle joint to connect the

leg to the cross member of the leg. I guess that sort of joint is more like an inside-out

mortise and tenon joint. I mostly used it because it leaves more of the material

for my upright intact.

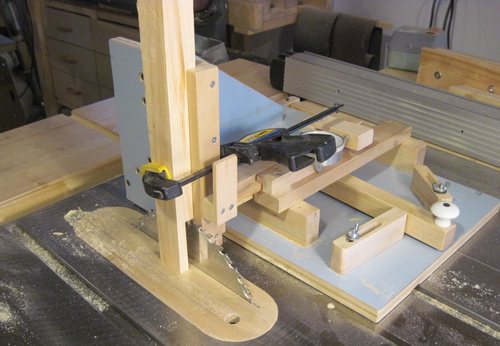

I cut a 1/2" (13 mm) wide notch into the end of my upright. The upright was from a piece

of scrap spruce, about 1 1/2" x 1 3/4" in size. With the 1/2" cut out from the middle,

that left two thirds of the leg intact. My quick-set

tenon jig was particularly handy for making this cut because it's very easy to move

the stock side to side between the two stops when making successive cuts.

I cut a 1/2" (13 mm) wide notch into the end of my upright. The upright was from a piece

of scrap spruce, about 1 1/2" x 1 3/4" in size. With the 1/2" cut out from the middle,

that left two thirds of the leg intact. My quick-set

tenon jig was particularly handy for making this cut because it's very easy to move

the stock side to side between the two stops when making successive cuts.

I used my caliper set at 1/2" and at 1" to scratch lines into the crosspiece to indicate

how deep I would have to cut into it.

I used my caliper set at 1/2" and at 1" to scratch lines into the crosspiece to indicate

how deep I would have to cut into it.

Next I cut out the notches on the crosspiece using my table saw sled.

Next I cut out the notches on the crosspiece using my table saw sled.

This sort of work goes faster if you use a dado blade, but seeing that I only had to make

one joint, it wasn't really worth installing the dado blade in my saw. Instead, I just made

a lot of cuts with a regular blade to get the material out.

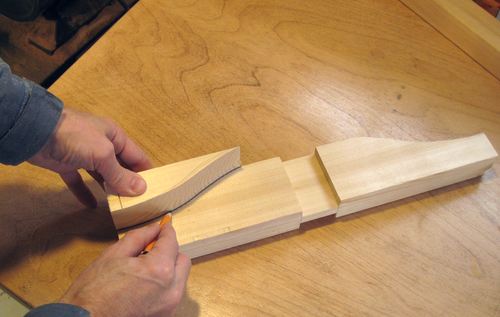

I cut the leg to be more of a sculpted outline. First I sketched the shape on the leg,

then I cut out one side, and used the scrap I had just cut away to mark a mirror

image of that cut on the other half of the leg crosspiece.

I cut the leg to be more of a sculpted outline. First I sketched the shape on the leg,

then I cut out one side, and used the scrap I had just cut away to mark a mirror

image of that cut on the other half of the leg crosspiece.

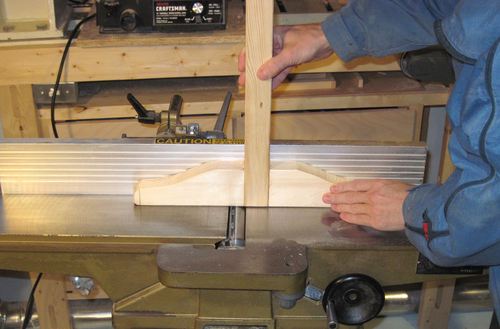

After gluing the leg upright onto the crosspiece, I shaped the bottom of the leg

to be just slightly concave. I did this by setting my jointer for a cut about 2 mm

deep (just a bit more than 1/16"), and made a half-pass with the jointer starting

about 5 cm (2") from the end, pushing the piece only so far that the cutter

was under the middle of the piece. I made the same cut starting from the other side.

This left the middle with a very slight

indentation. It's not enough of an indent to be noticeable unless you hold a ruler

to the bottom, but it's enough to make sure the leg won't rock back and forth if the

floor isn't completely fat.

After gluing the leg upright onto the crosspiece, I shaped the bottom of the leg

to be just slightly concave. I did this by setting my jointer for a cut about 2 mm

deep (just a bit more than 1/16"), and made a half-pass with the jointer starting

about 5 cm (2") from the end, pushing the piece only so far that the cutter

was under the middle of the piece. I made the same cut starting from the other side.

This left the middle with a very slight

indentation. It's not enough of an indent to be noticeable unless you hold a ruler

to the bottom, but it's enough to make sure the leg won't rock back and forth if the

floor isn't completely fat.

The brace to connect the top of the leg to the bottom of the extension table was made

out of some recycled birch wood.

The brace to connect the top of the leg to the bottom of the extension table was made

out of some recycled birch wood.

I cut a notch out of it that was the width of my post to help secure the post against

the mounting brace.

I cut the mounting piece to have some curves in it. This wasn't just to avoid bumping into

it with the knees. It also made the ends of the mounting piece narrow enough that I could

screw through them and into the table top.

I cut the mounting piece to have some curves in it. This wasn't just to avoid bumping into

it with the knees. It also made the ends of the mounting piece narrow enough that I could

screw through them and into the table top.

I cut a gap into the top end of the post, similar to the bridle joint at the bottom,

but this one only 1 cm (0.4") wide. A tenon on another piece of support fit in there.

The tenon is only secured with three screws, not glued in.

That way, I can take the third piece out again so that the extra leg can be made

flat for storing it. It might be a while before I host another dinner party

large enough that I need to extend the table,

but when I do I have my table extension ready.

And here's the leg attached to the bottom of the table top extension. The three blocks

on the left of it screw to the bottom of the main table.

And here's the leg attached to the bottom of the table top extension. The three blocks

on the left of it screw to the bottom of the main table.

It's not quite sturdy enough to sit on, but it does feel fairly secure, especially because the table it attaches to is really stiff and sturdy.

The next time I used this tagble extension, I switched to using a bigger piece of plywood for more guests. And for even more guests, I set up some tables in my workshop to use that as a party room.

Update 2018

I built that table extension in 2010. Afer we moved in 2017, we no longer used this table,

using this table instead. I needed an extension

for that table for when we have more guests, and I had a time lapse camera running while

I built that.

See also:

Building a kid's table

Building a kid's table

To my Woodworking website, or the Woodwork projects page.

Building the table this attaches to

Building the table this attaches to How to build a

How to build a Kitchen chairs

Kitchen chairs