I make single tenons with my quick set tenon jig,

and multiple tenons with my screw advance box joint

jig

but if I need to cut a tenon in the end of a piece of wood too long to put upright on

my table saw, I can cut them with this jig.

I make single tenons with my quick set tenon jig,

and multiple tenons with my screw advance box joint

jig

but if I need to cut a tenon in the end of a piece of wood too long to put upright on

my table saw, I can cut them with this jig.

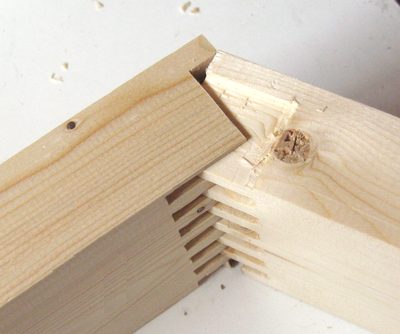

Cutting a double mortise.

Cutting a double mortise.

To make double tenons to go mate with the double mortises, I like to use my screw advance box joint jig, which can also index very precisely. This makes for double, triple, or more tenon joints that just align and fit perfectly, with no need to tweak them. And once it's set up, making a triple or a quadruple tenon joint is just a matter of turning the crank a few turns again, and cutting another slot.

I make single tenons with my quick set tenon jig,

and multiple tenons with my screw advance box joint

jig

but if I need to cut a tenon in the end of a piece of wood too long to put upright on

my table saw, I can cut them with this jig.

I make single tenons with my quick set tenon jig,

and multiple tenons with my screw advance box joint

jig

but if I need to cut a tenon in the end of a piece of wood too long to put upright on

my table saw, I can cut them with this jig.

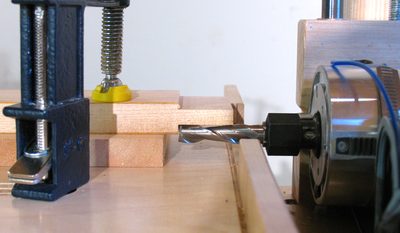

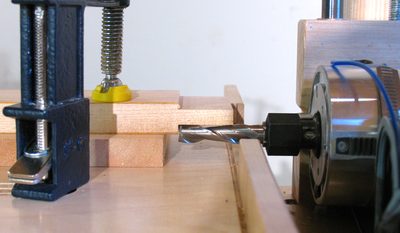

In this photo, I'm cutting a 3/8" tenon with a 1/2" router bit. After cutting the top, the router is lowered by exactly 14 turns on the crank, which lowers it by 7/8". With the 1/2" router bit, that leaves exactly a 3/8" tenon.

I experimented with making hidden box joints by cutting a series of open ended mortises

in the end of a piece of wood.

But I found that to be a bit much work

compared to cutting them with my screw advance

box joint jig, I also couldn't control how tight or loose this joint is, seeing that

I couldn't vary the width of the router bit's cut. I suppose I could vary the tightness

by slightly varying the spacing of the slots, but I didn't want to build a fancy

gear set like I did for the box joint jig. So I don't think

I will use this type of joint very much. Besides, I like showing off my joinery,

but you can't really show off a hidden joint.

I experimented with making hidden box joints by cutting a series of open ended mortises

in the end of a piece of wood.

But I found that to be a bit much work

compared to cutting them with my screw advance

box joint jig, I also couldn't control how tight or loose this joint is, seeing that

I couldn't vary the width of the router bit's cut. I suppose I could vary the tightness

by slightly varying the spacing of the slots, but I didn't want to build a fancy

gear set like I did for the box joint jig. So I don't think

I will use this type of joint very much. Besides, I like showing off my joinery,

but you can't really show off a hidden joint.

I might consider using half blind joints for some projects though. That would allow me to cut one part with the dado blade, which would allow me to shim the dado blade to get the right tightness of it. That would have been a good solution for the corners of this dresser, which I built before building this machine or the screw advance box joint jig.

By just cutting into the surface a little bit with the side of the bit,

a hinge mortise can be cut.

By just cutting into the surface a little bit with the side of the bit,

a hinge mortise can be cut.

Or by successively lowering and cutting more mortises, a square notch

can be cut in the side or in the middle of the work piece.

I figure this capability might come in handy to cut out the last few chunks

of the more complicated burr puzzles instead of

chiseling them out.

Or by successively lowering and cutting more mortises, a square notch

can be cut in the side or in the middle of the work piece.

I figure this capability might come in handy to cut out the last few chunks

of the more complicated burr puzzles instead of

chiseling them out.

My primary intent though was to build a machine that would make it easy to make double

tenon joints. But why stop at just two?

My primary intent though was to build a machine that would make it easy to make double

tenon joints. But why stop at just two?

This photo shows a "duodecouple" mortise and tenon joint. That is, 12 mortise and tenons side by side. I cut the tenons using my box joint jig.

The first time I tried this type of joint, it didn't fit. I then realized that my vertical adjustment screw actually had 16.1 turns per inch, not 16. Across just 6 fingers, this already made for a .015" (0.4 mm) error, which was enough to make the joint not fit.

Threaded rods are not all as precise as I had assumed. I had to check various hardware stores to find another threaded rod that had exactly 16 turns per inch, just like the one in my box joint jig. After I replaced the rod, the parts made in the two jigs mated perfectly.

Other than hand-carving the ends of the tenons round, there is no hand work in this joint. And it fit rather nicely!