Eliminating miter gauge play

Contributed by Paul Weatherby

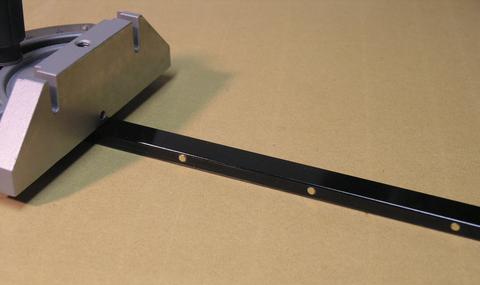

People often complain about their table saw miter gauge having too much play.

I find it annoying myself. Especially when you want consistent, accurate cuts

when making box joints. I saw that Delta makes a miter gauge with adjustable

screws to eliminate that problem. So I basically imitated their concept on

my own miter gauge. My only concern was that I might ruin my fairly new gauge

in the process.

People often complain about their table saw miter gauge having too much play.

I find it annoying myself. Especially when you want consistent, accurate cuts

when making box joints. I saw that Delta makes a miter gauge with adjustable

screws to eliminate that problem. So I basically imitated their concept on

my own miter gauge. My only concern was that I might ruin my fairly new gauge

in the process.

I chose brass screws over steel, because brass glides smoother and won't be

causing further wear in the miter slot. It is somewhat difficult to find

brass setscrews...so that means you have to cut the heads off each screw

and then cut a slot using a hacksaw. Not very difficult.

Use 10-32 brass machine screws. Tools: Drill press, vise,

center punch, #21 drill bit, tap & die set, cutting oil, hacksaw.

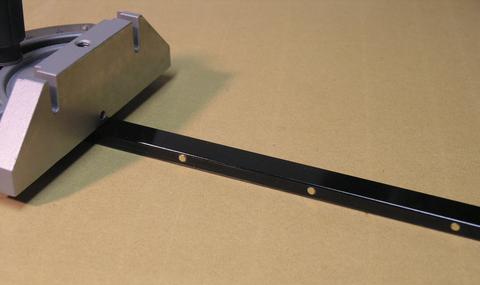

With normal table saw usage, the screws will wear very slowly.

You might have to tweak an adjustment once in two months....and usually

less than 1/4 of a turn.

With normal table saw usage, the screws will wear very slowly.

You might have to tweak an adjustment once in two months....and usually

less than 1/4 of a turn.

A small amount of Locktite on the screws may help to keep them from getting loose.

People often complain about their table saw miter gauge having too much play.

I find it annoying myself. Especially when you want consistent, accurate cuts

when making box joints. I saw that Delta makes a miter gauge with adjustable

screws to eliminate that problem. So I basically imitated their concept on

my own miter gauge. My only concern was that I might ruin my fairly new gauge

in the process.

People often complain about their table saw miter gauge having too much play.

I find it annoying myself. Especially when you want consistent, accurate cuts

when making box joints. I saw that Delta makes a miter gauge with adjustable

screws to eliminate that problem. So I basically imitated their concept on

my own miter gauge. My only concern was that I might ruin my fairly new gauge

in the process.