Box joined shelf brackets

After I built my fancy box joint jig,

I was keen to find more uses for it. I was running out of room on my

lumber rack so I decided to make some

shelving brackets to hold some lumber on the wall opposite to it near

the ceiling.

I wanted the individual fingers to be approximately 4 mm thick. This is thicker

than a saw blade, but still thinner than what can be done with a dado set.

Combining a thin kerf 7 1/4" blade and a regular kerf 7 1/4" blade produced

about the right thickness. With a 0.2 mm spacer between the blades, it turned out

to be just the right thickness to work with two turns worth of advance on

the 42 tooth gear against the 16 tooth gear on my fancy

geared box joint jig.

I was lucky that the two blades had exactly the same diameter. 7 1/4" blades

are often a bit larger or smaller than nominal, so not just any pair of blades

can be combined like that.

I wanted the individual fingers to be approximately 4 mm thick. This is thicker

than a saw blade, but still thinner than what can be done with a dado set.

Combining a thin kerf 7 1/4" blade and a regular kerf 7 1/4" blade produced

about the right thickness. With a 0.2 mm spacer between the blades, it turned out

to be just the right thickness to work with two turns worth of advance on

the 42 tooth gear against the 16 tooth gear on my fancy

geared box joint jig.

I was lucky that the two blades had exactly the same diameter. 7 1/4" blades

are often a bit larger or smaller than nominal, so not just any pair of blades

can be combined like that.

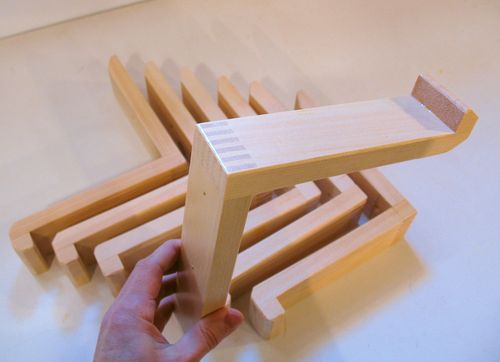

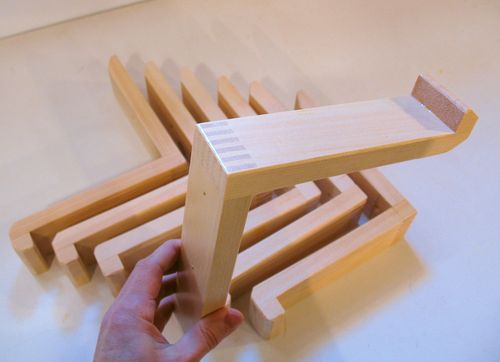

I made several L shaped box joined parts out of boards, one of which is shown at left.

I then ripped the width of the brackets

out of them afterwards. The piece at left was enough for two brackets.

I made several L shaped box joined parts out of boards, one of which is shown at left.

I then ripped the width of the brackets

out of them afterwards. The piece at left was enough for two brackets.

The only thing that holds the brackets up is the strength of the box joint.

Partly this is a bit of a test of the strength of a box joint. If I wasn't keen

on at the same time putting the joints to the test, I might have added some

sort of diagonal splines to the brackets, or used thicker material.

The only thing that holds the brackets up is the strength of the box joint.

Partly this is a bit of a test of the strength of a box joint. If I wasn't keen

on at the same time putting the joints to the test, I might have added some

sort of diagonal splines to the brackets, or used thicker material.

Or maybe I just made them that way because I can! :)

I loaded them up with the heaviest pieces of hardwood that I have. I don't dig

through those pieces as often, so it's ok to have them in a relatively awkward

spot. They are about 182 cm (6'1") off the floor - high enough for most people

not to bang their head against them. And the door frames

in my basement are lower at any rate.

I wanted the individual fingers to be approximately 4 mm thick. This is thicker

than a saw blade, but still thinner than what can be done with a dado set.

Combining a thin kerf 7 1/4" blade and a regular kerf 7 1/4" blade produced

about the right thickness. With a 0.2 mm spacer between the blades, it turned out

to be just the right thickness to work with two turns worth of advance on

the 42 tooth gear against the 16 tooth gear on my fancy

geared box joint jig.

I was lucky that the two blades had exactly the same diameter. 7 1/4" blades

are often a bit larger or smaller than nominal, so not just any pair of blades

can be combined like that.

I wanted the individual fingers to be approximately 4 mm thick. This is thicker

than a saw blade, but still thinner than what can be done with a dado set.

Combining a thin kerf 7 1/4" blade and a regular kerf 7 1/4" blade produced

about the right thickness. With a 0.2 mm spacer between the blades, it turned out

to be just the right thickness to work with two turns worth of advance on

the 42 tooth gear against the 16 tooth gear on my fancy

geared box joint jig.

I was lucky that the two blades had exactly the same diameter. 7 1/4" blades

are often a bit larger or smaller than nominal, so not just any pair of blades

can be combined like that.

I made several L shaped box joined parts out of boards, one of which is shown at left.

I then ripped the width of the brackets

out of them afterwards. The piece at left was enough for two brackets.

I made several L shaped box joined parts out of boards, one of which is shown at left.

I then ripped the width of the brackets

out of them afterwards. The piece at left was enough for two brackets.

The only thing that holds the brackets up is the strength of the box joint.

Partly this is a bit of a test of the strength of a box joint. If I wasn't keen

on at the same time putting the joints to the test, I might have added some

sort of diagonal splines to the brackets, or used thicker material.

The only thing that holds the brackets up is the strength of the box joint.

Partly this is a bit of a test of the strength of a box joint. If I wasn't keen

on at the same time putting the joints to the test, I might have added some

sort of diagonal splines to the brackets, or used thicker material.

Building a corner shelf

Building a corner shelf Double tenoned shelf supports

Double tenoned shelf supports Making shelf brackets

Making shelf brackets