Using the pantorouter for furniture repair

Dave Tenney writes:

I am the Facilities and IT manager for a Public Library. Kind of a weird job combination, but that's what happens when you work in trades to get through college ;)

On the facilities side we take care of eight buildings. Not only do we repair furniture, but we also build new pieces when time permits. We also use your tenon jig and the box joint jig in our work.

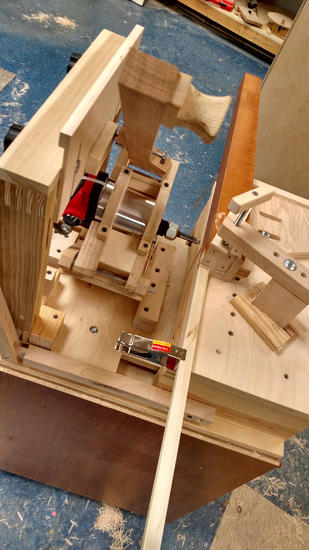

The pantorouter that I built for work was done in fits and starts over a 7 month period. I built mine at home in about a week! The one at work uses the followers from Kuldeep...I think we have the 10mm, 15mm and the 22mm. We also made templates similar to the commercial ones, which really makes setup easier. I had some trouble getting the oddball Milwaukee router mounted in it, but we had it on the shelf.

Repairing chairs

We normally get about four chairs each week in for repair. The problem with these chairs is that they are put together with dowels. This design may have worked OK in a situation where they would receive light use, but when subjected to the public on a daily basis they just don't hold up.

We have come up with a way to repair them that has held up quite well.

The failures are always at the point where the leg joins the apron with

two 3/8" dowels. Once this joint gets loose the days of the chair

staying together are limited.

First we mount the chair in the Pantorouter. This is the hardest part of

the repair! We then route a 1/2" x 2" mortise in the apron of the chair.

This mortise spans the area that the original dowel resided in.

First we mount the chair in the Pantorouter. This is the hardest part of

the repair! We then route a 1/2" x 2" mortise in the apron of the chair.

This mortise spans the area that the original dowel resided in.

Then we do the same thing with the legs.

Then we do the same thing with the legs.

In this photo you can see the assembly process. We are using a loose

tenon that we made from some hardwood scraps.

In this photo you can see the assembly process. We are using a loose

tenon that we made from some hardwood scraps.

What makes this so easy is that the references everything from the same face. As long as you have the template in the machine centered and square, there isn't a whole lot of places where you can screw it up.

Repairing Tables

We have about a dozen tables that are developing problems. Like the

chairs, they are not designed very well. They have no apron support for

the MDF top and all of them are bowing considerably in the middle.

We have about a dozen tables that are developing problems. Like the

chairs, they are not designed very well. They have no apron support for

the MDF top and all of them are bowing considerably in the middle.

You can see how chintzy the base construction for these table are. They

can barely stand up on their own without the support of the table top.

You can see how chintzy the base construction for these table are. They

can barely stand up on their own without the support of the table top.

Our solution to repairing these tables is to add a proper support system under them. We will be using 3/4 x 2 1/2" hard maple for the aprons. This is as tall as we could go and still provide clearance for the arms on the chairs to go underneath them.

Using the Pantorouter to mill tenons on the ends of the aprons.

Using the Pantorouter to mill tenons on the ends of the aprons.

Here are all the aprons completed.

Here are all the aprons completed.

Now we will make the mortises on the existing legs

Here is the assembled base. We also screwed in and additional support to

the inside of the leg...I thought about mortising these into the leg as

well, but I didn't want to complicate the glue up. Our shop is close to

the boiler and is usually pretty warm; glue sets up fast.

Here is the assembled base. We also screwed in and additional support to

the inside of the leg...I thought about mortising these into the leg as

well, but I didn't want to complicate the glue up. Our shop is close to

the boiler and is usually pretty warm; glue sets up fast.

More projects by Dave Tenney:

See also:

Another chair leg repair

Another chair leg repair

Box joint and tenon jigs

Box joint and tenon jigs Bandsaw

Bandsaw

The pantorouter

The pantorouter Scarf splice chair repair

Scarf splice chair repair

More reader projects

More reader projects