Making the bed posts

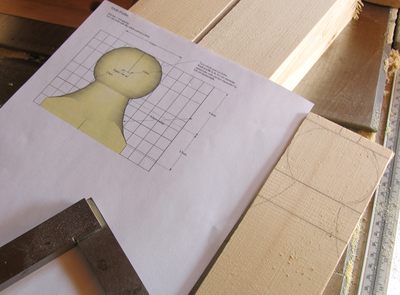

With the headboard assembled, it was time to tackle the posts. I sketched the approximate

shape onto one of the posts just to check my lines were good. The lines

across the post are still faintly visible even while the post is turning,

so these help me figure out where to start turning.

With the headboard assembled, it was time to tackle the posts. I sketched the approximate

shape onto one of the posts just to check my lines were good. The lines

across the post are still faintly visible even while the post is turning,

so these help me figure out where to start turning.

Here's turning one of the knobs on my lathe.

I messed up the second knob that I turned, so I had

to make another post. If I had been smarter about this, I would have made all four

posts to be long enough for the headboard. The footboard posts are about 15 cm shorter.

That way, if I messed up while turning one of the knobs, I could always cut it off,

and reused that post for the footboard.

Here's turning one of the knobs on my lathe.

I messed up the second knob that I turned, so I had

to make another post. If I had been smarter about this, I would have made all four

posts to be long enough for the headboard. The footboard posts are about 15 cm shorter.

That way, if I messed up while turning one of the knobs, I could always cut it off,

and reused that post for the footboard.

I left about a centimeter at the top of the post just for my dead center on my

lathe. Afterwards, I cut that part off. That way, I didn't have a hole in the top

of my post from where it was mounted on the lathe.

I left about a centimeter at the top of the post just for my dead center on my

lathe. Afterwards, I cut that part off. That way, I didn't have a hole in the top

of my post from where it was mounted on the lathe.

I then shaped the curvature of the very top of the post with my belt sander.

I put a soft pad behind the belt

of my belt sander to make it easier to sand a soft curve onto the top of the knob.

I then shaped the curvature of the very top of the post with my belt sander.

I put a soft pad behind the belt

of my belt sander to make it easier to sand a soft curve onto the top of the knob.

I moved around the post while doing this so that sanding belt was always sanding

towards the top center of the post.

Note how the Times-Roman 'O' is actually taller than the 'M' |

I actually wanted my posts to be about 6.4 cm wide. But gluing two 2x4's together,

even after planing them, I had just over 7 cm x 7 cm of material. Rather than cut them down

I actually wanted my posts to be about 6.4 cm wide. But gluing two 2x4's together,

even after planing them, I had just over 7 cm x 7 cm of material. Rather than cut them down

to final size, I decided to turn the knobs on them first, and then shave

about 3 mm off each side with my jointer afterwards. I had to take the 3 mm

off in one pass, and had to be careful to push it just far enough to trim the length

of the post, but not cut into the knob. The result was that the knob

was just slightly wider than the post.

to final size, I decided to turn the knobs on them first, and then shave

about 3 mm off each side with my jointer afterwards. I had to take the 3 mm

off in one pass, and had to be careful to push it just far enough to trim the length

of the post, but not cut into the knob. The result was that the knob

was just slightly wider than the post.

Aesthetically, it's better to have the knob just a bit larger than the post. If the knob was the same width as the post, it would actually look as though it was smaller than the post. It's a bit of an optical illusion that way. If you look at the times roman "MO" above, you can see that font designers use similar trickery to make the letters look as though they were the same size. Holding a straight piece of wood against the post and knob, you can see the square post and round knobs have similar proportions as the roman font square-ish 'M' and 'O'.

Next it was time to taper the legs. I rigged up a temporary tapering jig on

my table saw sled for this purpose. It consisted of a piece of 2x6 cut off at

90 degrees minus my tapering angle and with a 1" hole near the end which I used to clamp it

against the fence of my table saw sled.

Next it was time to taper the legs. I rigged up a temporary tapering jig on

my table saw sled for this purpose. It consisted of a piece of 2x6 cut off at

90 degrees minus my tapering angle and with a 1" hole near the end which I used to clamp it

against the fence of my table saw sled.

Next: Joining the posts to the headboard

Previous: Making the headboard

Back to Building a queen size bed

![]()