In a previous article I tried out a prototype 3D printed

dust collection hood that Kuldeep had sent me, then tried to improve on it,

but without success.

In a previous article I tried out a prototype 3D printed

dust collection hood that Kuldeep had sent me, then tried to improve on it,

but without success.

In a previous article I tried out a prototype 3D printed

dust collection hood that Kuldeep had sent me, then tried to improve on it,

but without success.

In a previous article I tried out a prototype 3D printed

dust collection hood that Kuldeep had sent me, then tried to improve on it,

but without success.

Some months later, Kuldeep sent me a production version of his dust collection hood to try out. Given problems I ran into earlier, I was skeptical.

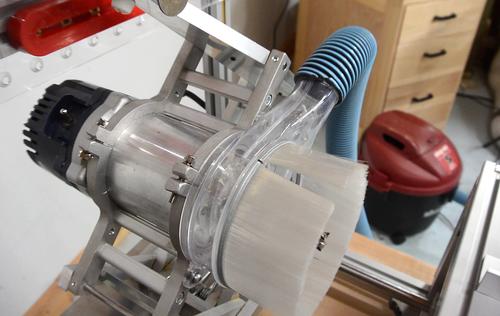

The production dust collection hood is made from clear plastic. It's also

flatter than the prototype, which means even with my cheap MasterCraft router,

I don't lose as much depth of cut as I did with the prototype.

The production dust collection hood is made from clear plastic. It's also

flatter than the prototype, which means even with my cheap MasterCraft router,

I don't lose as much depth of cut as I did with the prototype.

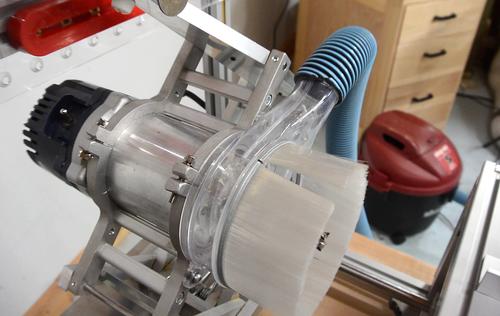

The hose connection is angled down slightly to help it pick up the chips

out of the bottom a little better. But this puts the hose about level

with the table, so there wasn't any room for my thicker 2.5" dust collector

hose and hose adapter.

The hose connection is angled down slightly to help it pick up the chips

out of the bottom a little better. But this puts the hose about level

with the table, so there wasn't any room for my thicker 2.5" dust collector

hose and hose adapter.

So instead I used a hose to my shop vac.

The dust collection hood is meant

to be used with a shop vac anyway, and I figure that should make clogging

less likely.

So instead I used a hose to my shop vac.

The dust collection hood is meant

to be used with a shop vac anyway, and I figure that should make clogging

less likely.

I was barely able to push this hose (which is from a swimming pool) onto the 40 mm fitting. Alternatively, I could have used a short piece of bicycle inner tube and some hose clamps to connect it.

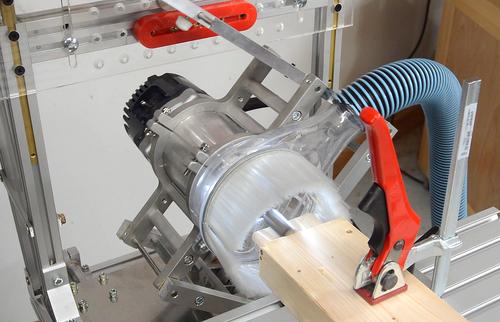

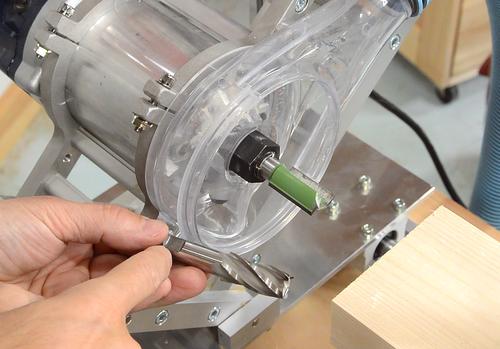

This time I used a spiral bit on the router. This one is actually a 4-flute

5/8" (16 mm) end mill with a 1/2" shank, but it also works as a router bit.

This time I used a spiral bit on the router. This one is actually a 4-flute

5/8" (16 mm) end mill with a 1/2" shank, but it also works as a router bit.

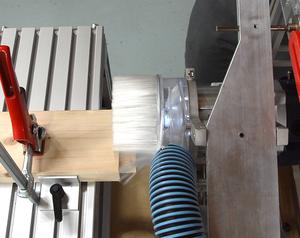

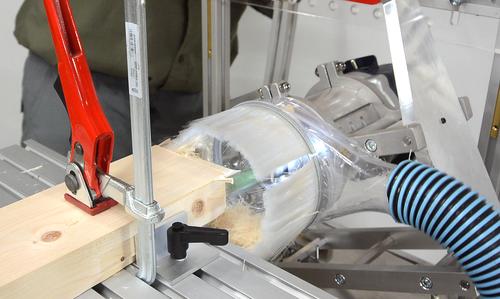

I cut a 1.5" (38 mm) long tenon on the end of a 2x4 (38x89 mm). I figure this is as big

a tenon as one would conceivably make a lot of. I cut this one fairly fast.

I cut a 1.5" (38 mm) long tenon on the end of a 2x4 (38x89 mm). I figure this is as big

a tenon as one would conceivably make a lot of. I cut this one fairly fast.

The dust collection performed very well. There were a few chips that got away because the brush bristles were pushed away by part of the tenon at some point, but the pantorouter itself stayed clean, and the dust collection hood never clogged.

My next test was to cut the same joint but cut a little slower.

This time, no chips got away. I was really surprised how much better this

worked from when I tried the prototype. I figured I'd change my test

set-up to be less optimal to see when it would stop working.

My next test was to cut the same joint but cut a little slower.

This time, no chips got away. I was really surprised how much better this

worked from when I tried the prototype. I figured I'd change my test

set-up to be less optimal to see when it would stop working.

My next change was to switch back to using my

homemade dust collector which

produces much less static pressure than the shop vac.

My next change was to switch back to using my

homemade dust collector which

produces much less static pressure than the shop vac.

To connect it, I cut a short length off the blue hose, then made an adapter out of a piece of bicycle inner tube to go between the smaller 40 mm hose and the 2.5" hose. It was hard to stretch the tube over the 2.5" hose end, but overall an elegant solution.

Testing it again, it still worked, still no clogging, still very few chips

getting away!

Testing it again, it still worked, still no clogging, still very few chips

getting away!

I figured it must be that the spiral bit helps a lot, so I switched back to

the 3/4" (19 mm)

router bit I used in my previous tests.

I figured it must be that the spiral bit helps a lot, so I switched back to

the 3/4" (19 mm)

router bit I used in my previous tests.

The spiral bit, I figured, makes it easier by throwing the chips back a little, and also makes for less straight chips.

And still it worked! A few more chips were left lying on the bottom

of the brush, but as more cutting is done, those would get sucked up, just

from all the swirling from the wind of the router bit and chips coming off

of it.

And still it worked! A few more chips were left lying on the bottom

of the brush, but as more cutting is done, those would get sucked up, just

from all the swirling from the wind of the router bit and chips coming off

of it.

I lowered the router's RPM to 13,000 and tried cutting very aggressively

to make larger chips. This time, the hood started to fill with chips from

time to time, even spilling a few here and there,

but it always cleared itself out soon after. Considering how hard I tired

to make it not work, it worked impressively well.

I lowered the router's RPM to 13,000 and tried cutting very aggressively

to make larger chips. This time, the hood started to fill with chips from

time to time, even spilling a few here and there,

but it always cleared itself out soon after. Considering how hard I tired

to make it not work, it worked impressively well.

Then I tried it with some heavy hard maple, again cutting hard and fast

at low RPMs for bigger chips. And still it worked. And I was cutting

much harder and faster than would be advisable for this type of wood.

Then I tried it with some heavy hard maple, again cutting hard and fast

at low RPMs for bigger chips. And still it worked. And I was cutting

much harder and faster than would be advisable for this type of wood.

There were some chips that got away, but it never clogged up. Some chips getting away is acceptable in my opinion, but clogging is not.

I was puzzled why this one worked so much better than the

prototype. I can only conclude that the smooth plastic surfaces allow

the chips to slide better, which would make clogging less likely.

I was puzzled why this one worked so much better than the

prototype. I can only conclude that the smooth plastic surfaces allow

the chips to slide better, which would make clogging less likely.

Moving the angle where the air it take off down a bit may also have helped.

Even though this hood is flatter than the prototype, I still lose

some potential depth of cut with my cheap router. Because I can cut tenons

in increments, the maximum length of a tenon is only limited by how far

the router bit extends beyond the collet, not by the length of the bit's

cutting edge.

Even though this hood is flatter than the prototype, I still lose

some potential depth of cut with my cheap router. Because I can cut tenons

in increments, the maximum length of a tenon is only limited by how far

the router bit extends beyond the collet, not by the length of the bit's

cutting edge.

But Mac Sheldon, who distributes the

pantorouters in the US recommends using a Porter Cable router with the

pantorouter. He sent me one. Aside from better quality,

this router also has a longer cylindrical body and a longer collet on

the front so that depth of cut is not limited by the dust collection hood.

But Mac Sheldon, who distributes the

pantorouters in the US recommends using a Porter Cable router with the

pantorouter. He sent me one. Aside from better quality,

this router also has a longer cylindrical body and a longer collet on

the front so that depth of cut is not limited by the dust collection hood.

You can buy the dust collection hood separately from the pantorouter. It should also be possible to attach it to the front of a homemade wooden pantorouter as well (but not the pantorouter XL), but I haven't tried this yet.

The hood is, unfortunately, rather expensive at $150 US. Why so much? Kuldeep tells me that getting the tooling made cost $20,000. It's a three piece injection mold, highly polished. And a jig for ultrasonic welding the halves together had to be made. And even per unit, it costs over $20 to get the plastic made, and the brush adds another $25. And with small production volumes, it's hard to amortize the high up-front costs. The things we buy the most are made by the million in China. This is not one of those.

It works well with a shop vac or my small dust collector, but a cheap 1 hp dust collector similar to this one would not have enough suction to avoid clogging. A downside of this dust collection hood is that it blocks the view of the workpiece. You can see a little bit through the clear plastic, but for the most part, you're working blind. Though, once you cut a lot of similar tenons, watching it cut becomes less important.

Normally, I set the pantorouter's depth stops so the router's plunge range is equal to the length of the tenon I'm cutting. That way, with the router against the back stop, I can use the tip of the router bit as a stop for positioning the workpiece.

But with the hood in place, it's better to be able to back the router way back to see if I didn't miss a spot when routing the tenon. But that requires an alternate solution for placing the workpiece at the right depth.

In the interest of disclosure, I do earn a royalty on these pantorouter sales, so it's in my best interest to promote them. But other than the free dust hood and the router that Mac Sheldon sent me, I was not compensated for doing this review.

I made a quick follow-up video answering two frequently asked questions about the dust collection hood:

This article was written in 2016. In 2021 Mac Sheldon has come up with a new dust hood

that flips open to use with routers that require two collet wrenches. He sent me one.

Now having an extra dust hood, I figured out how to mount it to a wooden pantorouter.