My primary motivation for making this box joint template was to

check the accuracy of my new pantorouter XL

after tweaking it for accuracy. I figured

such a wide joint would best expose distortion that the mechanism

might introduce.

My primary motivation for making this box joint template was to

check the accuracy of my new pantorouter XL

after tweaking it for accuracy. I figured

such a wide joint would best expose distortion that the mechanism

might introduce.

My primary motivation for making this box joint template was to

check the accuracy of my new pantorouter XL

after tweaking it for accuracy. I figured

such a wide joint would best expose distortion that the mechanism

might introduce.

My primary motivation for making this box joint template was to

check the accuracy of my new pantorouter XL

after tweaking it for accuracy. I figured

such a wide joint would best expose distortion that the mechanism

might introduce.

I needed some template that would guide the follower in vertical strokes.

Previously, I made a

template with slots wide enough for the follower bearing to slide in,

But with the new followers that I could put in backwards, I only needed

1/4" wide slots for the pin itself. So I stacked two saw blades with

a spacer in between and cut a series of slots across a hardwood board.

I needed some template that would guide the follower in vertical strokes.

Previously, I made a

template with slots wide enough for the follower bearing to slide in,

But with the new followers that I could put in backwards, I only needed

1/4" wide slots for the pin itself. So I stacked two saw blades with

a spacer in between and cut a series of slots across a hardwood board.

I taped an aluminium ruler to the work piece, and lined up even inch

marks with the slot in the sled to position the board for each cut.

That made for a slot every two inches. It's possible to align a line to

an edge to about a tenth of a millimeter by eye. With the 2:1

reduction of the pantograph, the template gives me a cut every inch on

the work piece. With a 1/2" cutter, that makes for 1/2" box joints.

I taped an aluminium ruler to the work piece, and lined up even inch

marks with the slot in the sled to position the board for each cut.

That made for a slot every two inches. It's possible to align a line to

an edge to about a tenth of a millimeter by eye. With the 2:1

reduction of the pantograph, the template gives me a cut every inch on

the work piece. With a 1/2" cutter, that makes for 1/2" box joints.

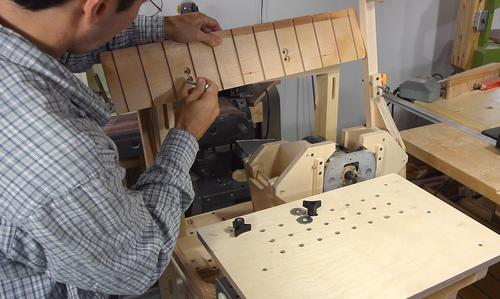

The template mounts to the template holder with some carriage bolts.

I cut recesses for the bolt heads so they wouldn't interfere wit the

pantograph mechanism. Plastic knobs on the back fasten down

the carriage bolts.

The template mounts to the template holder with some carriage bolts.

I cut recesses for the bolt heads so they wouldn't interfere wit the

pantograph mechanism. Plastic knobs on the back fasten down

the carriage bolts.

With the template mounted on the pantorouter, cutting out the slots

by running the follower pin down each slot in the template..

With the template mounted on the pantorouter, cutting out the slots

by running the follower pin down each slot in the template..

Chips are just flying upwards. I later started cutting these from the bottom moving up instead, so that the chips were thrown down instead of up.

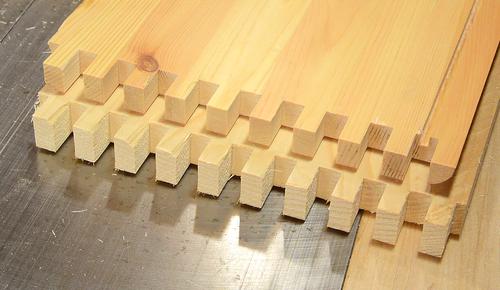

Finished cut. I have some tearout, but I also cut fairly fast.

Finished cut. I have some tearout, but I also cut fairly fast.

Another work piece cut, ready to check the fit.

Another work piece cut, ready to check the fit.

It's a good fit, though my screw advance box joint jig

can do better.

It's a good fit, though my screw advance box joint jig

can do better.

I also checked the fit with one of the boards flipped over. I figured that way,

the effects of distortion would become more evident. But it fit just as well

flipped as it did before.

I also checked the fit with one of the boards flipped over. I figured that way,

the effects of distortion would become more evident. But it fit just as well

flipped as it did before.

So I think my adjustments were a success.