Back in 1998, I wanted to test how the Blackberry pagers we developed would perform as they are moved sporadically through the local environment. With the pagers receiving at 900 mHz, moving them by even a few centimeters or changing the orientation can make a big difference in terms of reception. But the unit transmits at a slightly lower frequency, so the slight variations (fading) for transmission don't necessarily correlate to reception performance. You can never really know if a spot you put the pager is a good or a bad spot. That, and a pager worn on the belt will move sporadically as the wearer moves.

Playing with my Fischer-Technik construction set, I built a contraption that could move and rotate the pager in three axis at once, thus going through a large range of orientations and positions. Such a device would be useful for some of our tests. It would be even better if the device did not in itself interfere with radio waves, so of course, wood was an ideal material. I would have used wood regardless, mind you, but this was an extra reason!

I wasn't sure if the wooden gears would actually work when I started (it was the first time I attempted wooden gearing), but as I built and tested the parts, it all worked, so I kept at it until I had the finished machine.

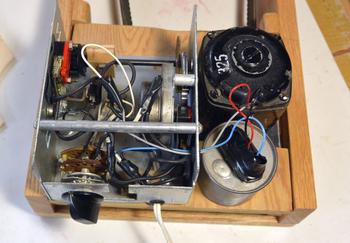

The whole thing is powered by an AC electric motor.

A timer motor, cams and switches (no electronics) turn the motor on periodically.

There's cams and switches to select continuous motion, or intermittent

motion at 12, 60, or 240 second intervals.

The whole thing is powered by an AC electric motor.

A timer motor, cams and switches (no electronics) turn the motor on periodically.

There's cams and switches to select continuous motion, or intermittent

motion at 12, 60, or 240 second intervals.

The machine has the limitation that it needs 120 volt AC power and isn't

very portable. When flying to different parts of the country,

taking this machine with me is not a practical option.

So I built a much smaller version, powered by one of those super efficient

Lego motors. Of course, once you start building with Lego, might as well build the whole

rotating machine out of legos

Update: 2014

At right, my "keyboard masher" for the initial GPRS blackberry, in 2001. I was,

at some point, tasked with investigating a sporadic "crazy SIM card"

problem, which was a "software" problem, but it only happened on some units.

I suspected it was a mechanical issue, with the SIM card holder right below the

keyboard. Typing on it could cause intermittent glitches. So I built a machine

to simulate typing. The machine uses three timer motors and over time presses

most of the keys on the keyboard. Leaving a device in this machine would

consistently trigger the problem on any device. So we were able to get a better

handle on it and test a software workaround.

More Wooden machines on my

Woodworking website

I left RIM (which later changed it's name to "Blackberry") in 2007

(more about that).

I left the machine behind as a colleague was still using it

from time to time. As of 2014, RIM has been struggling, and the

company decided that the cost of developing and maintaining their own GSM/GPRS/EDGE/3G

radio protocol stack was no longer justifiable by the now much lower sales volume.

Instead, they'd rely on chips and protocol stack firmware from Qualcomm. To put it into

perspective, Apple's iPhone and Google's Android also used a third party software for

the radio protocol stack instead of developing their own.

When the entire radio software team was laid off,

a co-worker had the presence of mind to take this

machine home with him and returned it to me. The machine had fallen into slight

disrepair. I got it working again, and made the video about it. This machine wasn't the

only wooden machine I built for testing stuff at RIM. That said, building machines

and fixtures was not part of my job, I just built them when I needed them.

When the entire radio software team was laid off,

a co-worker had the presence of mind to take this

machine home with him and returned it to me. The machine had fallen into slight

disrepair. I got it working again, and made the video about it. This machine wasn't the

only wooden machine I built for testing stuff at RIM. That said, building machines

and fixtures was not part of my job, I just built them when I needed them.