Making a spinning top on the lathe

Having made some improvements to my lathe it was time

for another small project to try it out. This time I made a small spinning top.

Having made some improvements to my lathe it was time

for another small project to try it out. This time I made a small spinning top.

The blank consisted of a 20 mm thick piece of maple with two pieces of mahogany glued to the side to get sufficient thickness for the wide part of the top. I cut off as much as I could on the bandsaw before putting it on the lathe.

The blank mounted on the lathe. I'm adding a drop of oil where the workpiece

spins on the cone of the tailstock.

The blank mounted on the lathe. I'm adding a drop of oil where the workpiece

spins on the cone of the tailstock.

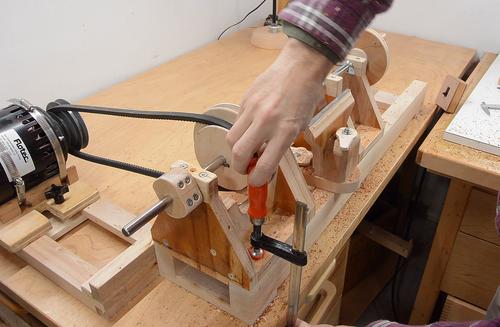

Before I made a motor mount, I clamped both the motor and the lathe to the workbench

to maintain belt tension. With the motor attached to the lathe, I could

use it without clamping it down. But with the lathe as light as it is, and the

vibrations from turning, the lathe started to wander away from me. So I clamped it

down again.

Before I made a motor mount, I clamped both the motor and the lathe to the workbench

to maintain belt tension. With the motor attached to the lathe, I could

use it without clamping it down. But with the lathe as light as it is, and the

vibrations from turning, the lathe started to wander away from me. So I clamped it

down again.

Turning the blank down sufficiently that it no longer has any flat spots.

Turning the blank down sufficiently that it no longer has any flat spots.

After that I shaped the main bulb. With the bulb shaped, I started

thinning down the stem and the point of the top. I thinned these down last

because once they are thin, the workpiece becomes too weak to do

much work on the wide bulb part of the top.

After that I shaped the main bulb. With the bulb shaped, I started

thinning down the stem and the point of the top. I thinned these down last

because once they are thin, the workpiece becomes too weak to do

much work on the wide bulb part of the top.

The last thing I did was to turn the point of it down to about 2 millimeters

thick -- thin enough for it to almost break. I half expected the

workpiece to go flying in the process of doing this.

The last thing I did was to turn the point of it down to about 2 millimeters

thick -- thin enough for it to almost break. I half expected the

workpiece to go flying in the process of doing this.

I then took the piece out of the lathe and cut it off on both ends.

I then took the piece out of the lathe and cut it off on both ends.

I wrapped some paper around the stem, put it in a drill, and then spun it

against my strip sander to finish

shaping the point.

I wrapped some paper around the stem, put it in a drill, and then spun it

against my strip sander to finish

shaping the point.

Testing it. Getting a one minute spin out of it was relatively easy.

Good enough for me.

Testing it. Getting a one minute spin out of it was relatively easy.

Good enough for me.

There are brass tops that you can buy that can spin for ten minutes straight. I wasn't aiming for that kind of record.

See also:

Tippe top

the self-inverting spinning top

Tippe top

the self-inverting spinning top

Bowl on the

Bowl on the An earlier bowl on the lathe

An earlier bowl on the lathe Building a lathe

Building a lathe Ball on the lathe

Ball on the lathe Captive ring baby rattle

Captive ring baby rattle More wooden toys

More wooden toys Refining the lathe

Refining the lathe Making coat hooks

Making coat hooks