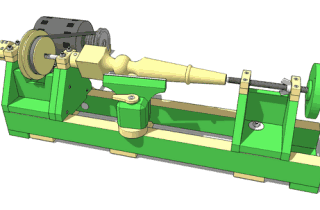

Turning a bowl on the homemade lathe

Having built a four jaw chuck for my lathe,

it was only natural to try it out by making a bowl with it.

Having built a four jaw chuck for my lathe,

it was only natural to try it out by making a bowl with it.

I glued together a blank out of some pieces of silver maple that I had milled with my homemade sawmill. I had some problems with the sawmill when I milled this wood so the piece was very crooked and the faces not parallel, but that didn't matter much for gluing together a bowl blank.

With the faceplate permanently attached to the drive shaft, I have to take the

drive shaft out to screw it onto the blank.

With the faceplate permanently attached to the drive shaft, I have to take the

drive shaft out to screw it onto the blank.

I used four 1" #6 screws. Placing the faceplate against the blank, I give each

screw a tap to mark the pilot hole locations...

I used four 1" #6 screws. Placing the faceplate against the blank, I give each

screw a tap to mark the pilot hole locations...

... then drill the pilot holes, at an angle because the holes in the faceplate

are also at an angle. I then screwed the faceplate on.

... then drill the pilot holes, at an angle because the holes in the faceplate

are also at an angle. I then screwed the faceplate on.

Now mounting the drive shaft back in the lathe (the split bearing blocks make

this relatively easy), and adding a drop of oil on each bearing just for good

measure.

Now mounting the drive shaft back in the lathe (the split bearing blocks make

this relatively easy), and adding a drop of oil on each bearing just for good

measure.

Making sure the blank clears the tool rest over it's full rotation.

Making sure the blank clears the tool rest over it's full rotation.

I started by turning the blank completely round, turning away any off-center

parts of the wood.

I started by turning the blank completely round, turning away any off-center

parts of the wood.

Lots of chips flying as I turn. I stalled the lathe a few times. The 1/3 HP

motor is on the weak side for turning a bowl at 1100 RPM.

Lots of chips flying as I turn. I stalled the lathe a few times. The 1/3 HP

motor is on the weak side for turning a bowl at 1100 RPM.

The outside of the bowl starting to take shape.

The outside of the bowl starting to take shape.

I used a skew chisel to turn the dovetail onto the bottom. This is

the same chisel I used to mill the dovetail into the jaws of

the chuck, so I know the angle will match.

I used a skew chisel to turn the dovetail onto the bottom. This is

the same chisel I used to mill the dovetail into the jaws of

the chuck, so I know the angle will match.

Bottom of the bowl done. You can see a swirl in the bottom.

As I was flattening it, the tool started to chatter. Instead

of backing off, I just finished flattening with the tool chattering.

This made for a nice swirl.

Bottom of the bowl done. You can see a swirl in the bottom.

As I was flattening it, the tool started to chatter. Instead

of backing off, I just finished flattening with the tool chattering.

This made for a nice swirl.

The lightness of this lathe makes it more prone to vibrations. Something made from heavy cast iron would be smoother. I could also have used bigger, heavier timbers. But lightness has its advantages. I don't have a place to leave this lathe permanently set up, and if it's lighter, it's easier to put it away. Next time, I'll clamp down the middle of the lathe bed to my workbench to give it more "mass".

Now I need to switch to the four jaw chuck. This is done by flipping

the drive shaft end-to-end.

Now I need to switch to the four jaw chuck. This is done by flipping

the drive shaft end-to-end.

Here, fitting the bowl onto the four jaw chuck.

Here, fitting the bowl onto the four jaw chuck.

With each jaw adjustable individually, centering is a manual operation.

I keep turning it to see which direction the bowl is displaced, then loosen

the jaw that I need to move the bowl towards and tighten the opposite jaw.

With each jaw adjustable individually, centering is a manual operation.

I keep turning it to see which direction the bowl is displaced, then loosen

the jaw that I need to move the bowl towards and tighten the opposite jaw.

This is very similar to centering with a four jaw chuck on a metal lathe.

Finished centering. The wobble was less than 1 mm.

Finished centering. The wobble was less than 1 mm.

Starting to hollow out the inside.

Starting to hollow out the inside.

Then lots of sanding. I sanded the outside before I flipped it over,

but neglected to take photos of that.

Then lots of sanding. I sanded the outside before I flipped it over,

but neglected to take photos of that.

What a lot of wood turners would do is now mount it by the rim with a much larger chuck and turn the bottom some more. But I liked the dovetail foot on this one, especially with the swirl, so I left it as is.

Someone suggested I should build a "longworth chuck" to hold the rim, but

it would be hard to make that work well in wood.

Someone suggested I should build a "longworth chuck" to hold the rim, but

it would be hard to make that work well in wood.

If I wanted to turn the foot, I'd make a larger faceplate and screw some blocks to hold the bowl by the rim, or if I was making a lot of bowls, maybe a much larger four-jaw chuck.

But I'm really not into bowl turning very much, so I'll not go through the trouble.

I could have sanded it better as well.

I could have sanded it better as well.

This was my first time turning a bowl from a relatively solid blank. It was a lot of material to remove, and I nearly filled a 20-liter bucket with shavings form this alone. And it's not even a very large bowl!

Last time I turned a bowl I started with a segmented blank, so I only had to remove a fraction of the material compared to this one.

But in my day to day life, I don't use any wooden bowls. So I really don't understand why some people are so into bowl turning on the lathe.

See also:

Homemade 4-jaw lathe chuck

Homemade 4-jaw lathe chuck Building a lathe

Building a lathe Lathe improvements

Lathe improvements Ball on the lathe

Ball on the lathe Captive ring baby rattle

Captive ring baby rattle Buy plans for the lathe

Buy plans for the lathe