John's in-place jointer knife honing method

John writes about his jointer honing operation:

First: I remember to UNPLUG the damn thing....

First: I remember to UNPLUG the damn thing....

Here's another way to find top dead center (tdc). I slide the magnetic base like a marking gauge. I'm not eager enough to scribe a mark, so I use tape to mark the position.

Then I use a C-clamp and whatever's handy (in this case, a drawer side and a

piece of aluminum sheet stock) to set up a stop for the blade.

Then I use a C-clamp and whatever's handy (in this case, a drawer side and a

piece of aluminum sheet stock) to set up a stop for the blade.

I made a rough calc. showing that I need about .028" of tangential movement/degree of back clearance on the knife:

Head diameter: 3.2"

3.2" x π = 10" circumference

10" / 360 = 0.028" per degree

I backed the right table off about 0.125" to give about 5 degrees of

clearance. 0.150" or 6 degrees might be a little better.

I backed the right table off about 0.125" to give about 5 degrees of

clearance. 0.150" or 6 degrees might be a little better.

There are existing holes in the head so I use a bungee and a piece of 1/8"

brass brazing rod to tension the blade against the stop.

There are existing holes in the head so I use a bungee and a piece of 1/8"

brass brazing rod to tension the blade against the stop.

Another view of the tension/stop setup. Repeatability from

blade to blade is paramount.

Another view of the tension/stop setup. Repeatability from

blade to blade is paramount.

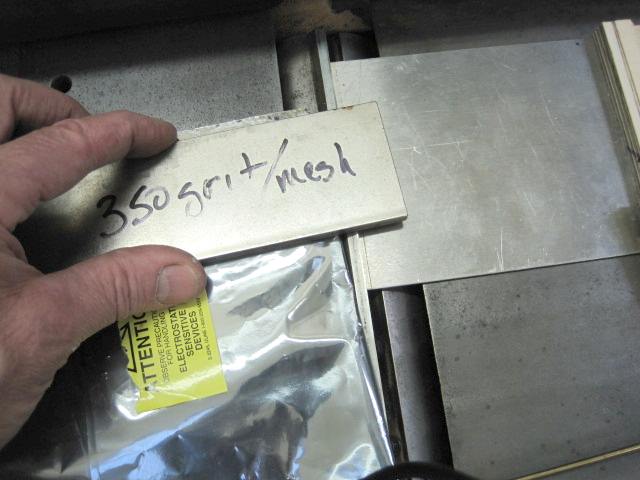

I started with a medium grit diamond stone with a circular motion to begin

honing. It takes a couple of minutes. I'm using a Mylar bag to

protect the table from the diamond. In actuality, a double layer of

wax paper seemed to have less sliding friction. I was too lazy to walk up

to the house to get some more waxed paper....

I started with a medium grit diamond stone with a circular motion to begin

honing. It takes a couple of minutes. I'm using a Mylar bag to

protect the table from the diamond. In actuality, a double layer of

wax paper seemed to have less sliding friction. I was too lazy to walk up

to the house to get some more waxed paper....

Here's another view showing the face of the diamond and the WD-40 I used to

lubricate it

Here's another view showing the face of the diamond and the WD-40 I used to

lubricate it

I worked my way around the three blades. I repeated the process with a

similar600 grit diamond. The blades come out remarkably

well aligned with the rear table.

I worked my way around the three blades. I repeated the process with a

similar600 grit diamond. The blades come out remarkably

well aligned with the rear table.

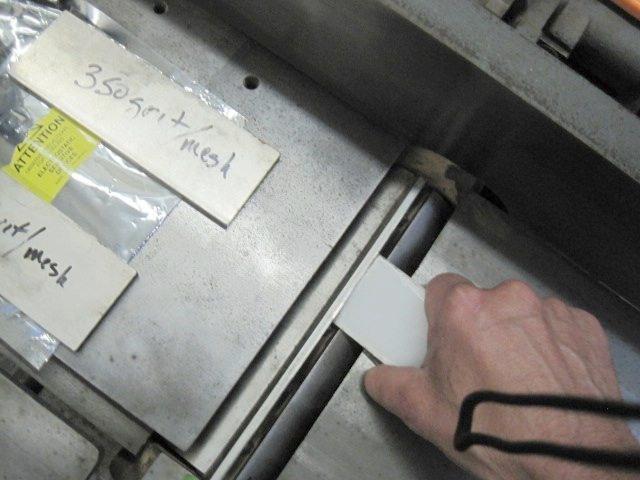

The honing resulted in a slight burr on the blades which I removed

with a piece of Lexan.

The honing resulted in a slight burr on the blades which I removed

with a piece of Lexan.

It would be interesting, if the blades were nicked, to begin this process with a much coarser diamond, say about 150 mesh. If I were buying the diamond 'stones' again, I'd definitely spring for the 8" length diamonds, instead of the 6" length.

Thaaatttttt's all folks......

See also:

Setting and adjusting jointer knives |

Freehand sharpening jointer knives |

Homemade jointer |

Handplane sharpening for barbarians |