The floor in question is supported by 2x10's every 16" with a span of 14'.

The floor in question is supported by 2x10's every 16" with a span of 14'.

The floor in question is supported by 2x10's every 16" with a span of 14'.

The floor in question is supported by 2x10's every 16" with a span of 14'.

In metric, that's one piece of lumber 38x240mm every 40cm, spanning 4.2m. My European readers will probably scoff at how lightly we build houses here, but keep in mind that our houses also cost much less to build.

With floor joists this long and this far apart, this was pushing it a bit; no wonder that floor felt a little bit soft.

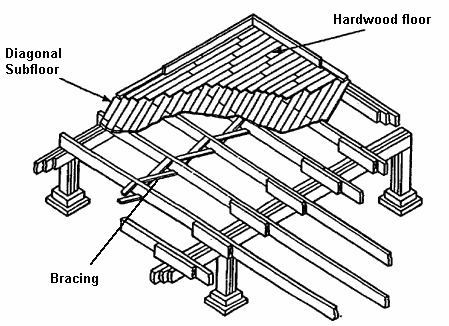

When a hardwood wood floor is placed on a floor of this sort, it's normal to orient the floor boards

so they run across the joints. This helps bridge support between the joists, and also helps to connect

the joists together. Before plywood came into use, the subfloor was typically nailed in at

a 45-degree angle. The idea was that the subfloor couldn't be parallel to the joists, and shouldn't

be parallel to the floor boards, so it had to be put in at an angle. If you look up between the

floor joists of most 1950s or earlier houses, you will see the subfloor boards at a 45-degree angle.

When a hardwood wood floor is placed on a floor of this sort, it's normal to orient the floor boards

so they run across the joints. This helps bridge support between the joists, and also helps to connect

the joists together. Before plywood came into use, the subfloor was typically nailed in at

a 45-degree angle. The idea was that the subfloor couldn't be parallel to the joists, and shouldn't

be parallel to the floor boards, so it had to be put in at an angle. If you look up between the

floor joists of most 1950s or earlier houses, you will see the subfloor boards at a 45-degree angle.

Tara's house, being built in the 1980s, has a plywood subfloor, so no need for this. But the hardwood floor boards were nailed in parallel to the joists. So whatever stiffening the floor boards should have provided didn't happen here. I'd consider this a slight defect in construction, but an upside of it was that the floor, though it had lots of give, didn't creak. Basically the hardwood floor boards, oriented the way they are, aren't add much stiffening, but at the same time, the flexing isn't pulling on the nails either.

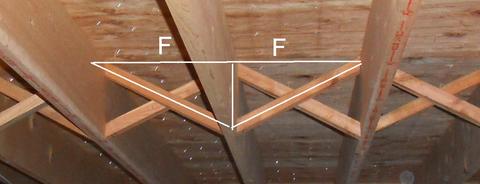

Diagonal braces are usually applied to the middle of the span of long floor joists.

These help stiffen the floor by tying the joists to each other. If you look at the

members highlighted in white, you can see they form two triangles. These ensure that the segments labelled

'F' stay in line with each other. So you stand directly over the joist between those,

the load is spread over the adjoining joists as well. With all the braces

together, these form a sort of truss-like structure to stiffen up the floor.

Diagonal braces are usually applied to the middle of the span of long floor joists.

These help stiffen the floor by tying the joists to each other. If you look at the

members highlighted in white, you can see they form two triangles. These ensure that the segments labelled

'F' stay in line with each other. So you stand directly over the joist between those,

the load is spread over the adjoining joists as well. With all the braces

together, these form a sort of truss-like structure to stiffen up the floor.

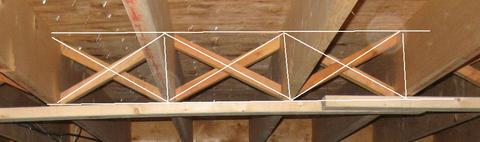

A much better truss-like structure would be achieved if there was another member along the bottom, so

that they form a sort of cross lattice girder. And this was my strategy for stiffening

up this floor. So I attached some 2x4's to the bottom of the floor joists.

A much better truss-like structure would be achieved if there was another member along the bottom, so

that they form a sort of cross lattice girder. And this was my strategy for stiffening

up this floor. So I attached some 2x4's to the bottom of the floor joists.

I put two 4" long #12 screws into each floor joist.

I put two 4" long #12 screws into each floor joist.

My preference would have been to use 16' long 2x6's for this job (stiffer and fewer joints needed), but there were some 8' long 2x4's already in the garage, so I used those.

Because the space underneath the floor is an unused crawlspace, I also added some posts roughly

every third joist. These really helped stiffen up the floor.

Because the space underneath the floor is an unused crawlspace, I also added some posts roughly

every third joist. These really helped stiffen up the floor.

I cut the posts slightly too long, then put them in at an angle and used a hammer to drive them to vertical. After that, I toe-nailed them to the 2x4s running along the bottom of the joists.

It's always a challenge working away from home. I didn't bring a circular saw,

so I had to cut the lumber using a pruning saw. It cuts fairly fast, but not very cleanly. But for

this job, it was ok.

It's always a challenge working away from home. I didn't bring a circular saw,

so I had to cut the lumber using a pruning saw. It cuts fairly fast, but not very cleanly. But for

this job, it was ok.

The final result would not win any prizes for beauty or precision. I positioned the posts to all fit into

various crevices in the bedrock below, so the positions, and even the angles are a little bit irregular.

But these posts are not there to hold

the house up, just to stiffen the floor. If any were to come out, nothing would collapse.

The final result would not win any prizes for beauty or precision. I positioned the posts to all fit into

various crevices in the bedrock below, so the positions, and even the angles are a little bit irregular.

But these posts are not there to hold

the house up, just to stiffen the floor. If any were to come out, nothing would collapse.

The floor of the house sure felt different after I put these in. It had lost it's bounce.