Working on a table, I needed some thin dowels about 1/4" or 6 mm or in diameter.

I didn't feel like spending a lot of time setting things up.

Working on a table, I needed some thin dowels about 1/4" or 6 mm or in diameter.

I didn't feel like spending a lot of time setting things up.

So I cut some 6 mm square pieces from some very hard wood to use as blanks.

I then used a small palm plane to bevel the corners so it's roughly octagonal. If it was entirely soft wood I was using them with, I could have just hammered them into undersized holes like nails. But they were going into particle board, which might split from that.

So I used a drill bit of the right size to set a spacer on my belt sander leaving just

the right amount of space.

So I used a drill bit of the right size to set a spacer on my belt sander leaving just

the right amount of space.

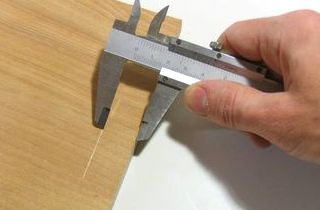

The dowels turned out to be a tiny bit larger than the drill I set them to.

Rather than make adjustments to the block, I just switched to a slightly bigger

drill bit for drilling the holes.

See also:

Back to my Woodworking website

Then spinning the octagonal pieces between the block and the sanding belt.

Then spinning the octagonal pieces between the block and the sanding belt.

I made a simple disposable jig for drilling the holes.

I made a simple disposable jig for drilling the holes.

The jig also served as a depth stop.

The jig also served as a depth stop.

Then applying glue to the dowel and the hole...

Then applying glue to the dowel and the hole...

... and hammering them in place.

... and hammering them in place.

This method is good for dowels of about 4-8 mm. I wouldn't want to use it for anything

bigger, but for making dowels 8 mm or smaller, it's probably the best method, unless you have

a half round router bit of the right size.

Paul Grundbacher's dowel maker

Paul Grundbacher's dowel maker

![]()

Making dowels, pencil sharpener method

Making dowels, pencil sharpener method Making dowels with a half-round router bit

Making dowels with a half-round router bit Bamboo skewers as 5mm dowels

Bamboo skewers as 5mm dowels conic dowels and spindles on the jointer

conic dowels and spindles on the jointer More about using dowels

More about using dowels More shop tricks

More shop tricks