While working on my new 26" bandsaw, I ended up doing tons of clamping for the

wheels,

frame, and

table glue-ups. With all that clamping,

I realized that the standard cylindrical bar-clamp handle is a terrible

shape ergonomically.

While working on my new 26" bandsaw, I ended up doing tons of clamping for the

wheels,

frame, and

table glue-ups. With all that clamping,

I realized that the standard cylindrical bar-clamp handle is a terrible

shape ergonomically.

While working on my new 26" bandsaw, I ended up doing tons of clamping for the

wheels,

frame, and

table glue-ups. With all that clamping,

I realized that the standard cylindrical bar-clamp handle is a terrible

shape ergonomically.

While working on my new 26" bandsaw, I ended up doing tons of clamping for the

wheels,

frame, and

table glue-ups. With all that clamping,

I realized that the standard cylindrical bar-clamp handle is a terrible

shape ergonomically.

I was also using some of my new long-reach clamps, which have square star knobs on them. They have star knobs because I had these bolts with knobs already kicking around when I built them. And that shape turns out to be very easy to turn.

So I wanted to try a handle of that shape on my bar clamps.

So I wanted to try a handle of that shape on my bar clamps.

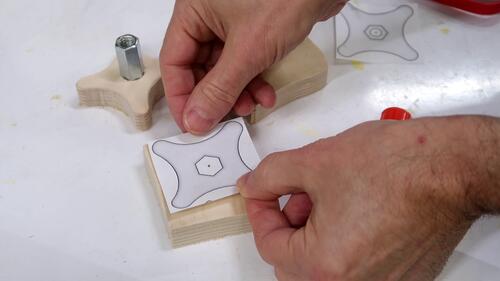

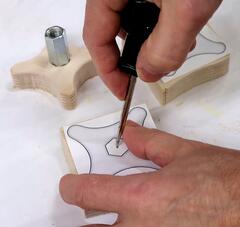

I used the same knob template that I made for my 26" bandsaw plans for the clamps.

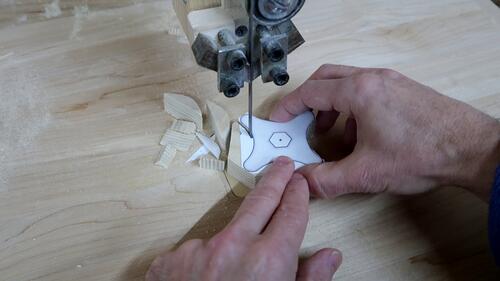

And cut them out on my yet-unfinished

26" bandsaw.

And cut them out on my yet-unfinished

26" bandsaw.

I clipped my convex-shape to the platen of my

1"x42" strip sander, then sanded the inside curve of the knobs.

When sanding inside curves this way, it's important to keep moving

side-to-side or the edges of the belt start digging into the wood.

I clipped my convex-shape to the platen of my

1"x42" strip sander, then sanded the inside curve of the knobs.

When sanding inside curves this way, it's important to keep moving

side-to-side or the edges of the belt start digging into the wood.

Then drilling out a 19 mm center hole.

Then drilling out a 19 mm center hole.

But how to fit these onto the clamp handles, which are not consistently sized,

nor consistently round?

But how to fit these onto the clamp handles, which are not consistently sized,

nor consistently round?

The answer is, of course, the pantorouter

I used a circular template I made made long ago for another project and

a bearing to guide the router to cut a 19 mm tenon using

a 1/2" (12.7 mm) router bit.

I used a circular template I made made long ago for another project and

a bearing to guide the router to cut a 19 mm tenon using

a 1/2" (12.7 mm) router bit.

After a test piece, I clamped one of my cheaper bar clamps onto the table

and routed around it.

After a test piece, I clamped one of my cheaper bar clamps onto the table

and routed around it.

But I hadn't clamped it down firmly enough and it slipped while I was routing, screwing up the cut!

Fortunately,

there was plenty of clamp handle left, so I just cut off the screwed up bit

and cut it again.

Fortunately,

there was plenty of clamp handle left, so I just cut off the screwed up bit

and cut it again.

One clamp I messed up twice, leaving just a stub of a handle. But I liked that one

better, so I shortened the other ones as well.

One clamp I messed up twice, leaving just a stub of a handle. But I liked that one

better, so I shortened the other ones as well.

I made knobs for 12 of my clamps, including four of the nicer Bessey clamps.

I made knobs for 12 of my clamps, including four of the nicer Bessey clamps.

After that, A quick test to see how it feels. I hooked two clamps to each other,

one with the orignal handle, one with the knob. I then tightened the one with

the original handle as far as I would normally tighten it, then tried tightening

the knob. It was still easy to turn. I then oiled the threads on both and

repeated the test. Still, the knob was much easier to turn.

After that, A quick test to see how it feels. I hooked two clamps to each other,

one with the orignal handle, one with the knob. I then tightened the one with

the original handle as far as I would normally tighten it, then tried tightening

the knob. It was still easy to turn. I then oiled the threads on both and

repeated the test. Still, the knob was much easier to turn.

Of course, the handles might be made deliberately hard to turn to prevent over-tightening, so I will have to be careful how much I tighten them now.

There are some down sides. For example, for clamping

a stop-block to a table saw sled, the knob get caught on the edge of the saw's table.

Also not ideal for tight spaces. So I won't be modifying all my clamps.

There are some down sides. For example, for clamping

a stop-block to a table saw sled, the knob get caught on the edge of the saw's table.

Also not ideal for tight spaces. So I won't be modifying all my clamps.

The wider knobs can also be a problem on the clamp rack, though they turned

out less of a problem than I expected.

The wider knobs can also be a problem on the clamp rack, though they turned

out less of a problem than I expected.

And finally, using them for an actual glue-up. I still had a piece that needed to

be glued to the front of my 26" bandsaw frame.

And finally, using them for an actual glue-up. I still had a piece that needed to

be glued to the front of my 26" bandsaw frame.

I really like how these knobs feel in the hands and how they are much easier to

operate. And I can also quickly twirl the knob with one finger if I need to

back the screw up a lot.

I really like how these knobs feel in the hands and how they are much easier to

operate. And I can also quickly twirl the knob with one finger if I need to

back the screw up a lot.

Making long-reach C-lamps (2011)

Making long-reach C-lamps (2011) The pantorouter machine (2010)

The pantorouter machine (2010) Building a holddown clamp (2010)

Building a holddown clamp (2010) Homemade 26" bandsaw (2021)

Homemade 26" bandsaw (2021) A box full of Microjig, and clamps that I like (video, 2020)

A box full of Microjig, and clamps that I like (video, 2020) Bar clamp extender (video, 2022)

Bar clamp extender (video, 2022)