Building a hold down clamp

While working on a my pantorouter machine,

I needed another hold down clamp, similar to one of these

drill press hold down clamps I had bought from

Busy Bee Tools.

While working on a my pantorouter machine,

I needed another hold down clamp, similar to one of these

drill press hold down clamps I had bought from

Busy Bee Tools.

But it was a Sunday, so the store was closed, and besides, the store is at the far

end of town.

So I thought I might try making a hold down clamp out of one of those really

cheap Chinese made C-clamps that I never use anyway.

I started by milling a cavity into a piece of wood to fit around the top part of the

C-clamp. I milled out this cavity with a router using the new machine that I'm working

on (I'll write about that machine some other time), but my slot mortiser would have done just

as well.

I started by milling a cavity into a piece of wood to fit around the top part of the

C-clamp. I milled out this cavity with a router using the new machine that I'm working

on (I'll write about that machine some other time), but my slot mortiser would have done just

as well.

I had to remove the bar handle to fit it in the block. It took a few

iterations to get it to fit perfectly. I was lucky the that paint

rubbed off on the wood just a bit, so I could tell where I needed to carve away more

wood after each fitting.

I had to remove the bar handle to fit it in the block. It took a few

iterations to get it to fit perfectly. I was lucky the that paint

rubbed off on the wood just a bit, so I could tell where I needed to carve away more

wood after each fitting.

Having come this far, I figured my experiment was worth destroying the C-clamp for.

Having come this far, I figured my experiment was worth destroying the C-clamp for.

This really wasn't a very good clamp, but what I liked about it for this application is

that it had a very coarse ACME thread, so that it doesn't take many turns to open and

close it.

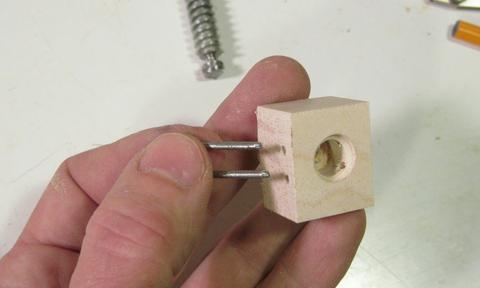

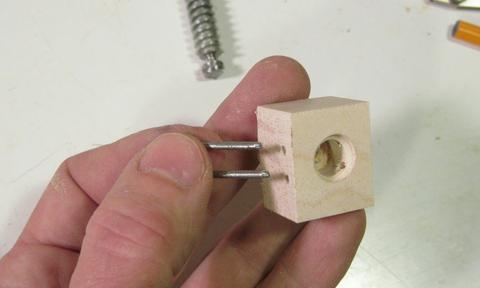

Two drywall screws next to the clamp hold it in the cavity. I originally thought I might

mount it by drilling some holes in the clamp, but judging by the type of sparks

I got when I cut it with an angle grinder, I realized that the steel on this clamp

was relatively hard and would have been difficult to drill. Fortunately, drywall

screws, with their relatively wide flat head, were able to hold it from the side.

Two drywall screws next to the clamp hold it in the cavity. I originally thought I might

mount it by drilling some holes in the clamp, but judging by the type of sparks

I got when I cut it with an angle grinder, I realized that the steel on this clamp

was relatively hard and would have been difficult to drill. Fortunately, drywall

screws, with their relatively wide flat head, were able to hold it from the side.

One of the reasons I didn't use that clamp much was because the end of the screw is

just a piece of sheet metal. The sheet metal has sharp edges and doesn't spin

freely enough, so it marks up the wood as it's tightened. At this point I was

tempted to cut up one of my better clamps to avoid that problem, but the

cavity I carved in the wood only fit this particular clamp.

So I figured making a new pressure pad was the easier route.

One of the reasons I didn't use that clamp much was because the end of the screw is

just a piece of sheet metal. The sheet metal has sharp edges and doesn't spin

freely enough, so it marks up the wood as it's tightened. At this point I was

tempted to cut up one of my better clamps to avoid that problem, but the

cavity I carved in the wood only fit this particular clamp.

So I figured making a new pressure pad was the easier route.

But how? I don't have a metal lathe to shape the end of the screw.

So I spun the shaft up in my drill press, and used

an angle grinder to shape a knob on the end, plus a groove behind it. I'm really

surprised how well this crude technique actually works!

Two nails in the groove could hold the pressure pad onto the end of the screw

Two nails in the groove could hold the pressure pad onto the end of the screw

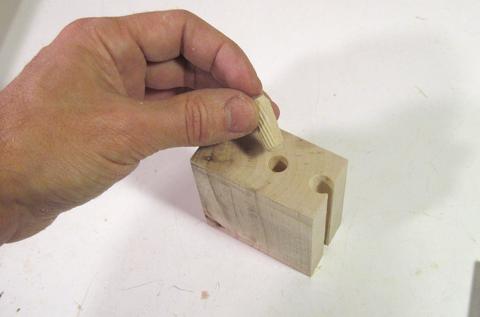

I used a block of maple for the new clamp head. Instead of two nails, I ground the head

off a nail and then bent it into a U shape.

I used a block of maple for the new clamp head. Instead of two nails, I ground the head

off a nail and then bent it into a U shape.

There's nothing in the bottom of the pressure pad to push against the metal, it's just the

end of my bolt pushing against the wood. I used hard maple, so that should help. But this

hold down clamp won't see crazy amounts of pressure, so this should do.

The photo is from when I checked the fit. I rounded the corners on it after that photo

was taken.

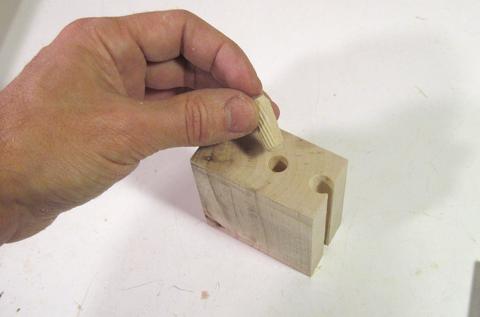

I had to destroy the original bar that served as a clamp handle to get it out.

I had to take it out to be able to inset the clamp into the cavity. I also would

not have been able to mount the screw in my drill press without taking the handle out.

So now I had to make a new handle. I used

a piece of maple, with a hole just slightly smaller than the end of the shaft. I

pressed the end of it into the block and then drove a 1/8" (3 mm) diameter

pin through the hole to go through the hole in the shaft.

I had to destroy the original bar that served as a clamp handle to get it out.

I had to take it out to be able to inset the clamp into the cavity. I also would

not have been able to mount the screw in my drill press without taking the handle out.

So now I had to make a new handle. I used

a piece of maple, with a hole just slightly smaller than the end of the shaft. I

pressed the end of it into the block and then drove a 1/8" (3 mm) diameter

pin through the hole to go through the hole in the shaft.

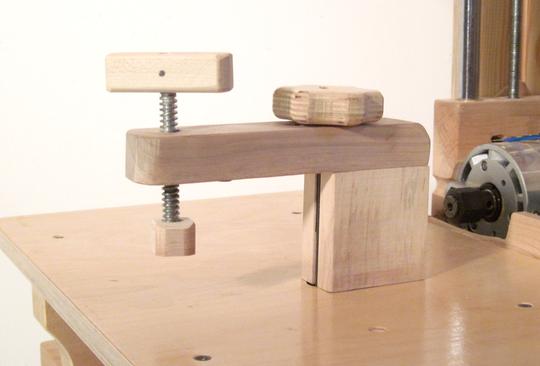

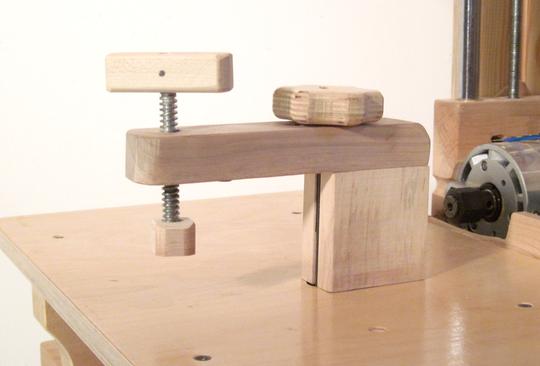

So now I had a bar with a hold down screw on one end. This bar needs to be mounted some

distance above the work table on my machine. I made a spacer to fasten this bar

above the table.

So now I had a bar with a hold down screw on one end. This bar needs to be mounted some

distance above the work table on my machine. I made a spacer to fasten this bar

above the table.

I drilled a hole for a bolt right on the edge of the spacer block. Basically, the bolt that

holds the clamp might as well be as far forward as it can be, so I'd get maximum leverage

from the bolt.

With my drill partially breaking out the front of the slot, I opened that slot

along its length on the bandsaw (looks better that way). I also added a dowel pin

to help align that block with the bar.

With my drill partially breaking out the front of the slot, I opened that slot

along its length on the bandsaw (looks better that way). I also added a dowel pin

to help align that block with the bar.

The bar can be put on the block in two different positions to vary how far it extends.

Mounting the bar and block on the table holds them together, so there's no need

to have any other means of attaching the block to the bar.

I made another knob to go on the end of the bolt that holds the hold down in place.

I cut it out of 3/4" (19 mm) Baltic birch, and mounted a T-nut in it.

I made another knob to go on the end of the bolt that holds the hold down in place.

I cut it out of 3/4" (19 mm) Baltic birch, and mounted a T-nut in it.

I figured it would be best if this one had a different shape as the handle

for the screw. That way, I'd be less likely to absent mindedly loosen the whole

hold down when I only meant to loosen the stock.

With all the work I ended up doing to the cheap Chinese clamp to make it suitable,

I realized I would have done just as well if I started with a piece of 1/2" threaded rod instead.

That way I could have just used a T-nut instead of carving that complicated cavity for

the C-clamp bit.

With all the work I ended up doing to the cheap Chinese clamp to make it suitable,

I realized I would have done just as well if I started with a piece of 1/2" threaded rod instead.

That way I could have just used a T-nut instead of carving that complicated cavity for

the C-clamp bit.

The one advantage of having started with the clamp is that I ended up with a

coarse ACME thread on my clamp. That means this clamp tightens faster and easier

than if I had used 1/2" threaded rod, which would have had an 11 TPI thread.

The clamp is strong enough for use with router based machines such as my

slot mortiser or the new machine that I'm

working on. But the forces I encounter on my

horizontal boring machine are far greater, so I'll stick with the less elegant

but more heavy duty hold down design

on that machine the way it is.

I started by milling a cavity into a piece of wood to fit around the top part of the

C-clamp. I milled out this cavity with a router using the new machine that I'm working

on (I'll write about that machine some other time), but my slot mortiser would have done just

as well.

I started by milling a cavity into a piece of wood to fit around the top part of the

C-clamp. I milled out this cavity with a router using the new machine that I'm working

on (I'll write about that machine some other time), but my slot mortiser would have done just

as well.

While working on a my pantorouter machine,

I needed another hold down clamp, similar to one of these

drill press hold down clamps I had bought from

Busy Bee Tools.

While working on a my pantorouter machine,

I needed another hold down clamp, similar to one of these

drill press hold down clamps I had bought from

Busy Bee Tools.

Slot mortising machine

Slot mortising machine The pantorouter

The pantorouter Making long-reach

Making long-reach Toggle clamp for the

Toggle clamp for the