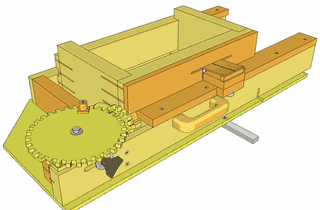

Gerald Finch's box joint jig

Gerald Finch writes

Matthias,

I just finished building the box joint jig from your plans. It works very well, though I had some difficulty at first in getting a perfect fit for the fingers. I had to tweak the size of the dado with shims to get it to match the distance movement of the gear advance. Perhaps some simple instructions on the use of the jig would be helpful along with the plans.

Matthias comments:

I have several videos on that topic online. But the fact increasing the

finger spacing makes the joint tighter is always counterintuitive.

I often make adjustments in the wrong direction myself.

It serves the same purpose and keeps the box tightly against the dovetail. To do this I added maple guide rails on the back side of the box, cut a shallow stopped groove in the box rail and made the gib from some 3/8 polycarbonate that I had. (I would have preferred HDPE, but I did not have any on hand.) The gib is held in place with 4 screws that can also adjust the amount of spring tension. I rubbed the wood and gib with paraffin wax, which makes it slide nicely.

Matthias comments:

I thought about adding tension this way as well, but opted for the idler

at the front to avoid pushing the guide rails apart. Pushing on the guide

rails apart puts a bending stress on the floor of the jig, which,

depending on what it's made of, may cause it to bow up with time.

Never had a need to place a clamp where the idler roller is myself.

Since the plywood also is prone to tearout on the exit of the cut, I added a renewable chip breaker inside the frame that is flush with the inside surface of the box. It works well.

Matthias comments:

What a cool idea!

Thanks again for your great design.

Thanks again for your great design.

Jerry Finch

Matthias comments:

thanks for those pictures. I think one of those jigs goes really well with a

format style table saw. Attaching it directly to the sliding table is

more elegant than a bar sliding in the slot. And you can use the jig

to cut box joints, even

without a dado blade

See also:

Back to screw advance box joint jig