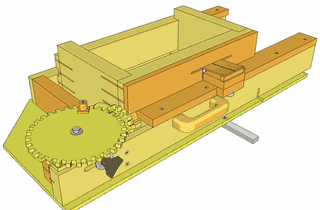

Bob Owen's motirized box joint jig

|

Bob sent me a video of his motorized box joint jig. Bob was running into shoulder pain from pushing the jig across is saw thousands of time producing bee boxes, so he made a jig to do this for him. The idea is more to relieve one operation than to automate everything. Turning off the switch after the stroke is automated though (watch where he switches it on). Bob writes about the jig: I thought you might want to see what I am doing with the great finger joint jig you designed and John made for me. ( I wish he would make them still) This video is not edited or complete but you get the idea. I only use the jig to make boxes for bee hives, two sizes: 6 5/8" wide boards and 9 5/8". So I have a 7/8" dado on the table saw. I attached two bar clamps to always be in place and added a spring loaded squeeze board to keep the boards flush against the side. We make thousands of these boards and my shoulders and back were killing me last year after a few hours of pushing the jig back and forth. So recently I rigged up the wooden gears and simple switch to the variable speed drill. I had a speed control switch next to the toggle switch (on hand) but it was rated one amp under the drill and failed after two days use. I later bought a bigger amp rated controller but in the mean time put a threaded bolt against the drill switch and it keeps on ticking. So haven't installed the new speed switch yet. I expected the toggle switch to fail too and will need to get a more durable switch, but so far it has cycled on and off over 10K times without fail. On the 6 5/8" boards I can cut the fingers on each set of 6 boards in about 2 minutes or considering down time 150 boards per hr. Much quicker than before and sooo much less pain. I want to thank you for designing the jig. Without it I have no idea what I would have done to make these cuts. A hauncher used by the big boys would cost more that all the machinery in my entire shop. And I really have my doubts the hauncher would be much faster. You still have to load it and turn the boards. And all the other table saw jigs were too sloppy. By the way my company is OzarkCedarHives.com Thanks and God bless, Bob Owen |

Bob is not the only one to use a screw advance box joint jig. See this video on making Bee box finger joints

And you may wonder what a hauncher is. Here's a hauncher on YouTube

See also:

Back to screw advance box joint jig