Why I wrote BigPrint

BigPrint is a program to facilitate making large and accurate multi-page printouts on ordinary ink jet or laser printers.

When I originally wrote my online gear template generator,

I realized that paper templates are a surprisingly good way to make accurate layouts for gears.

I later wrote a more sophisticated gear generator

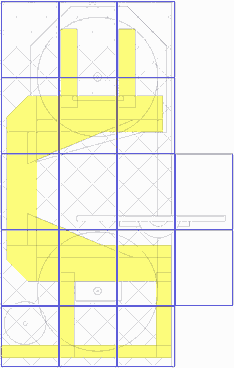

which added a grid of diagonal lines that could be overlaid to help align printouts.

This feature turned out to be really helpful for aligning the pages of a large

printout when gluing them together.

When I originally wrote my online gear template generator,

I realized that paper templates are a surprisingly good way to make accurate layouts for gears.

I later wrote a more sophisticated gear generator

which added a grid of diagonal lines that could be overlaid to help align printouts.

This feature turned out to be really helpful for aligning the pages of a large

printout when gluing them together.

I had the idea for a multi-page printout when I made my bandsaw plans. It worked out well, so I wrote BigPrint to automate the process |

But dividing a large bitmap into smaller bitmaps to fit on individual sheets of paper turned out to be fairly laborious. I wrote a small program to help with the basic segmenting, but it wasn't at all "easy to use".

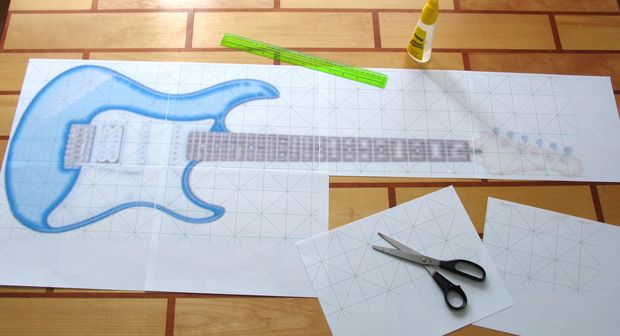

I used BigPrint to check the design of my Pantorouter |

By January, I got back to working on BigPrint, but it wasn't until mid-February that I got it ready. What added to the time was writing a tutorial, with lots of pictures, and documentation. But even while documenting it, I still came up with more improvements - such as the ability to make measurements, or making it easy to only print a subset of the pages.

I'm not actually planning on building a guitar, but it was an interesting shape to test BigPrint with |

So that's what's been taking up my time for the last little while.

Play around with the free evaluation version of BigPrint. It can do everything the full version can do, but it prints a big "Eval" over everything. Still, the eval is useful for making measurements on drawings. You can also use it to check the accuracy of your printer. You'll be surprised how accurate cheap ink jet printers are!

Go to the BigPrint page.

Back to my Woodworking website.