A simple trick for measuring the strain on the blade is

to clamp a caliper to the blade

A property of all ferrous metals is that so long as they are not stressed to the point of permanent deformation, they all stretch by a nearly equal amount as a function of tension. The factor of stretch as a function of how much tension is applied is called the Young's modulus. Published tables provide this number for various materials.

A simple trick for measuring the strain on the blade is to clamp a caliper to the blade |

Bandsaw tension gauges are just devices that measure the relative stretch of the blade by attaching to two points on the blade, and measuring how far those points move relative to each other. They tend to be kind of expensive.

A trick for measuring the relative stretch is to just clamp a caliper to two points on the saw blade with very low tension, and then tension the blade and measure how much the caliper opened up by. On larger bandsaws, there is enough room between the blade guides to do this. On smaller bandsaws, its best to either remove the blade guide, or measure on the left side.

For example, if the blade was observed to stretch by .002" over a 4" span, that makes for a relative stretch of:

| 0.002" | = 0.0005 |

| 4.000" |

Now multiplying that by Young's modulus:

0.0005 * 29,000,000 PSI = 14500 PSI

Now, to convert that to actual tension in pounds, we need to multiply that by the cross-sectional area of the saw blade in square inches.

A typical 1/4" blade will have a thickness of about 0.026", and an actual width of 0.190". I'm measuring the width at the base of the teeth, seeing that the tips of the teeth don't really help hold blade tension. The tips do change things a tiny little bit though, but we'll ignore that.

So my 1/4" saw blade has a cross-sectional area of:

0.190" x 0.026" = 0.00494 square inches

Now multiply by the pounds per square inch calculated earlier:

0.00494 square inches * 14500 PSI = 71.63 pounds

Bandsaw blades can take 15,000 PSI of tension. A greater limit is

how much force your bandsaw can take. From my measurements, given the limitations

of a typical bandsaw, it's just about impossible to over-tension any but the narrowest

of bandsaw blades. 70 pounds is more than my 14" bandsaw is capable of.

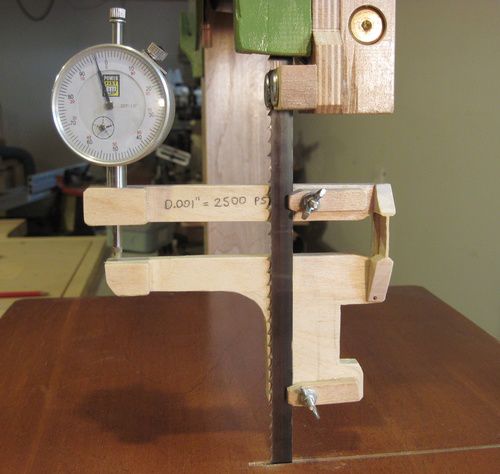

My tension gauge clamps to the blade at two points 4" apart. The thin connection on the

right side of my gauge is designed to flex, and acts as a sort of "hinge" in my gauge.

The dial indicator is mounted 2.9 times as far from the hinge as the blade attachment

points, so that the relative stretch of the blade is multiplied, through leverage by

2.9 times where the dial indicator measures it. Thus, every 0.001" change on my dial

indicator is equal to 0.001" / 2.9 = 0.000345" of strain. 0.00345" of strain over

four inches is equal to a relative strain of 0.0000862. Multiplying that by the Young's

modulus for steel (29,000,000 PSI) comes to 2500 PSI.

I only have to do this calculation

once, and I wrote the result onto my indicator. Now, to measure balde tension in PSI, I

Just take the number of thou (how many lines the needle moved after applying tension)

times 2500 to get the tension in the blade in PSI.

So I figured I should test that tension gauge by applying a known amount of tension

to the blade. So I took an old blade, attached it to a ceiling joist in my workshop, clamped

a vise grip to it, and pulled myself up by the blade while reading my tension gauge.

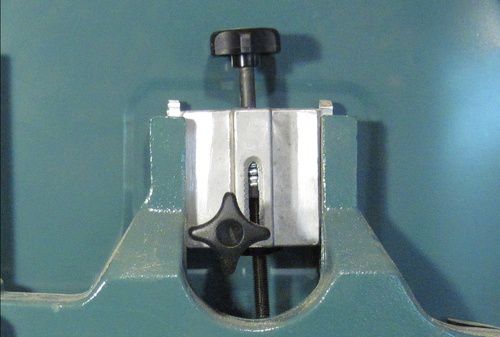

I held the top end of the blade by clamping a drill press vise to a ceiling joist. But I had

visions of it coming loose, and having a vise and heavy clamps all hailing down on my head.

So wore my snowboarding helmet while doing this just to be safe.

I found it really hard to get a good steady reading while pulling myself up by the

vise grips. It seemed I was close, but I wanted to get a better reading.

So I clamped my drill press vise to the setup, and used a piece of 2x4 as a lever for pulling

the blade. The lever's fulcrum is the top of the post on the right. The jack is one and

a half times as far from the fulcrum as my blade, so any reading on the scale has to be

multiplied by 1.5 to get the pounds of tension in the blade. I zeroed the scale with

the jack already on it, so I wouldn't have to subtract its weight afterwards.

Then I started pumping. I pumped the jack until the scale read 100 pounds, so

I had 150 pounds on the blade. Working out the tension using my tension meter, I got

nearly the same result. So I knew my homemade tension gauge was pretty close.

That meant that the unexpectedly low tension readings I got on my 14" saw were

actually correct.

Next I pumped on the jack to try to break the blade. I got up to about 360 pounds of

tension when it started to slip in my vise, so I never managed to actually break the blade.

But when I released the tension, I found that my tension

spring didn't return to its original length. I also noticed that it

had a bit of a bend to it. So at a measly 65 pounds of tension, my tension spring

had started to bend!

I also ground a point onto the end of the tensioning screw, which should help it

stay centered in the divot.

I then started looking around for a replacement tension spring. I checked various stores

that sell springs, but couldn't find anything that was stiff enough and fit the space.

Online, the best I could find was $20 + shipping from the US.

This seemed a bit much for just a spring, so I decided to leave it be for the time being.

Instead, I made a small spacer block to bring the spring back to its old length.

(Update: Lee Valley Tools also sells replacement springs, also for $20).

In the past, I had typically only cranked that spring at most a third of the way to the

top, and as long as I'm not resawing, the blades cut just fine with that amount of tension.

On my homemade bandsaw, I was able to get the tension up to 150 pounds, whereas I thought

it could do 200 pounds. But 150 pounds on my home made wooden bandsaw is still more than

twice as much as my cast iron framed 14" bandsaw. I did find that at that tension, the wheels

started to creak just a little bit, so I had to make some

more refinements to the wheels to fix that.

Update 2021:

Its been 11 years since I made that tension gauge, and I haven't used since I made it, not even once.

I just go by feel by pusing the blade to the side with my fingers a bit. There's no such thing

as the "right"tension, only adequate tension and inadequate tension. Blades don't break from

over tensioning, so it's all a matter of what you are comfortable in terms of what your saw

can take.

Home made tension gauge

Because clamping a caliper to a bandsaw blade is awkward and can damage the blade,

I built myself a simple bandsaw tension gauge using some birch plywood and a dial indicator.

Because clamping a caliper to a bandsaw blade is awkward and can damage the blade,

I built myself a simple bandsaw tension gauge using some birch plywood and a dial indicator.

When I used my homemade tension gauge on my 14" bandsaw, the tension readings

were much lower than I expected. I knew that the typical cheap 14" bandsaw's

tension reading on the back tends to suggest tensions that are on the low side,

but I it seemed like the tension that my gauge read was too low by more than a factor

of two. I checked my calculations several times, but couldn't find an error.

When I used my homemade tension gauge on my 14" bandsaw, the tension readings

were much lower than I expected. I knew that the typical cheap 14" bandsaw's

tension reading on the back tends to suggest tensions that are on the low side,

but I it seemed like the tension that my gauge read was too low by more than a factor

of two. I checked my calculations several times, but couldn't find an error.

So I was thinking, "if only I had a setup like I had for my

joint strength tests".

And then it occurred to me to just reuse that very same setup!

So I was thinking, "if only I had a setup like I had for my

joint strength tests".

And then it occurred to me to just reuse that very same setup!

Tensioning up the 14" saw

Knowing that the blade tension in my 14" bandsaw was much lower than I had always thought it

was, I figured I should try cranking it up all the way to see how much I'd get.

I had it up about two thirds of the way, with my meter indicating a strain that worked

out to 65 pounds when the tensioning screw started sliding dangerously sideways.

With the screw just pushing against the plain casting, and nothing

holding it centered on the bottom, it just started to wander sideways as I turned it.

I figured I should fix that problem first.

Knowing that the blade tension in my 14" bandsaw was much lower than I had always thought it

was, I figured I should try cranking it up all the way to see how much I'd get.

I had it up about two thirds of the way, with my meter indicating a strain that worked

out to 65 pounds when the tensioning screw started sliding dangerously sideways.

With the screw just pushing against the plain casting, and nothing

holding it centered on the bottom, it just started to wander sideways as I turned it.

I figured I should fix that problem first.

To keep the end of the screw from wandering in the future, I drilled a small

divot into the casting where the screw pushes against it

To keep the end of the screw from wandering in the future, I drilled a small

divot into the casting where the screw pushes against it

So the morale of the story is that all along, the saw was cutting just fine with much less

tension than I thought I had. It hadn't bothered me because I never actually knew how low

the tension was. Until I replace that spring, I know I can reasonably

crank the tension half way up, which will give me maybe 40 pounds of tension. While

that is not a lot, it's a lot more than I usually tensioned the saw to, so it should be adequate.