Steven's bandsaw

Steven writes:I bought your plans in about 2014 November.

With support from my family and school, I finally finished building my bandsaw from your plans. I have read a lot of other readers building their 16" bandsaw, and so far, for a couple of years, the youngest to build one was 15 years old. However, right now I am 14 years old - just 3 weeks till I am 15, but doesn't it still make me the youngest person to build a bandsaw? I took over 130 photos from the build, and I am showing some here. Anyway, thanks for such comprehensive plans, they were just a joy to follow through.

All the parts for the bandsaw frame: I took apart a big old pine

cabinet and cut it into bits to make the bandsaw frame. It had a thick coat of

varnish that prevented any glue sticking to, so I used a belt sander to strip

it down. I made the inner mortise and tenon a very tight fit and used a

calliper along with a dial indicator to make super accurate cuts. In my

experience, it's better to start off very accurately.

All the parts for the bandsaw frame: I took apart a big old pine

cabinet and cut it into bits to make the bandsaw frame. It had a thick coat of

varnish that prevented any glue sticking to, so I used a belt sander to strip

it down. I made the inner mortise and tenon a very tight fit and used a

calliper along with a dial indicator to make super accurate cuts. In my

experience, it's better to start off very accurately.

Dry fitting everything first to make sure they fitted. The one to

one drawings were very useful for doing this. I broke one of the triangles when

making it, so the two clamps on top of the frame in the picture is me gluing

the triangle back together.

Dry fitting everything first to make sure they fitted. The one to

one drawings were very useful for doing this. I broke one of the triangles when

making it, so the two clamps on top of the frame in the picture is me gluing

the triangle back together.

Gluing down all the layers, here in the picture all the clamps I

had, so I had to glue the frame layers one by one, it took over a week to do

but there was nothing I could do. Luckily, at Christmas, I got six clamps

as a Christmas present. The build article of your 14" bandsaw was very helpful -

I therefore avoided gluing on the bottom rails, so I could drill holes for the

bottom wheel mount afterwards.

Gluing down all the layers, here in the picture all the clamps I

had, so I had to glue the frame layers one by one, it took over a week to do

but there was nothing I could do. Luckily, at Christmas, I got six clamps

as a Christmas present. The build article of your 14" bandsaw was very helpful -

I therefore avoided gluing on the bottom rails, so I could drill holes for the

bottom wheel mount afterwards.

The frame all glued up, some of the varnish I haven't sanded off yet.

The frame all glued up, some of the varnish I haven't sanded off yet.

I don't have a jointer or table saw big enough to flatten any

of the sides, so I had to flatten everything with a

smoothing plane, belt sander and orbital sander. The split top workbench I

built was very useful for clamping the frame securely.

I don't have a jointer or table saw big enough to flatten any

of the sides, so I had to flatten everything with a

smoothing plane, belt sander and orbital sander. The split top workbench I

built was very useful for clamping the frame securely.

These are the parts for the top and bottom wheel mount. In my area,

hard Maple and any domestic hardwood are very hard to find, exotic hardwood in

comparison is much easier to find. I picked up a huge red gum post at work (my

kind employer gave it to me). I also collected a lot of Australian Jarrah

from my local hardware store. The other thicker bits of hardwood pieces were

mainly made by laminating thinner pieces of Jarrah.

These are the parts for the top and bottom wheel mount. In my area,

hard Maple and any domestic hardwood are very hard to find, exotic hardwood in

comparison is much easier to find. I picked up a huge red gum post at work (my

kind employer gave it to me). I also collected a lot of Australian Jarrah

from my local hardware store. The other thicker bits of hardwood pieces were

mainly made by laminating thinner pieces of Jarrah.

This is an old motor that I took out of a green Dewalt radio arm saw,

which a good friend of mine gave to me. I made a simple holder for it so I

could bolt it down to the frame.

This is an old motor that I took out of a green Dewalt radio arm saw,

which a good friend of mine gave to me. I made a simple holder for it so I

could bolt it down to the frame.

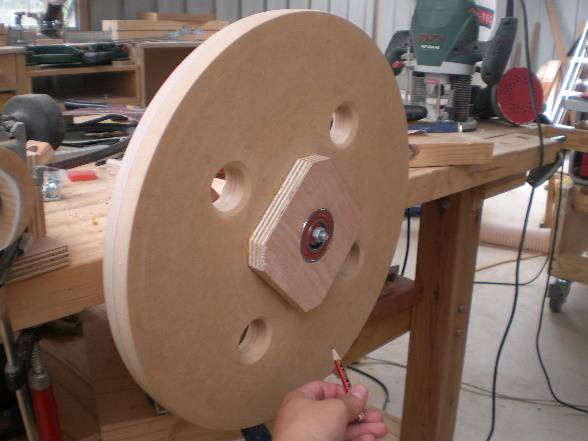

Here in the picture is me gluing the layers of the wheels together

with all my old clamps plus 6 more new ones. I used a router with a circle

cutting jig to cut out the individual wheel layers, and lined up the centres

as I glued it together.

Here in the picture is me gluing the layers of the wheels together

with all my old clamps plus 6 more new ones. I used a router with a circle

cutting jig to cut out the individual wheel layers, and lined up the centres

as I glued it together.

Turning down the wheels while it is turning on its own bearings. I

had no turning experience at all, not even the most basic turning tools. But with

a regular half inch chisel I was still able to true up the wheels.

Turning down the wheels while it is turning on its own bearings. I

had no turning experience at all, not even the most basic turning tools. But with

a regular half inch chisel I was still able to true up the wheels.

Both the wheels had over 1 mm of

side wobble, and I couldn't get the wobble out while turning it on its own

bearings. So I used a dial indicator to see where the high spots

were, and sanded it down. I sanded both sides of the wheels

carefully until I had less than 0.1mm of wobble. The wheels were made of

MDF, so they were very well balanced and I didn't need to adjust it at all.

Both the wheels had over 1 mm of

side wobble, and I couldn't get the wobble out while turning it on its own

bearings. So I used a dial indicator to see where the high spots

were, and sanded it down. I sanded both sides of the wheels

carefully until I had less than 0.1mm of wobble. The wheels were made of

MDF, so they were very well balanced and I didn't need to adjust it at all.

Both the wheels coated with some varnish and a bicycle inner tube

stretched around. I don't have a metal tap to tap the threads in the shaft ends

for a screw, so at that moment I only had a block of wood clamped to the shaft

so the wheels don't come off. I later tapped the threads into the ends of the

shaft when school started. I asked my design and technology teachers to assist

me in tapping the threads.

Both the wheels coated with some varnish and a bicycle inner tube

stretched around. I don't have a metal tap to tap the threads in the shaft ends

for a screw, so at that moment I only had a block of wood clamped to the shaft

so the wheels don't come off. I later tapped the threads into the ends of the

shaft when school started. I asked my design and technology teachers to assist

me in tapping the threads.

Here is me gluing in the rest of the bottom frame, since I have

already mounted the bottom wheel mount.

Here is me gluing in the rest of the bottom frame, since I have

already mounted the bottom wheel mount.

Here is me using a handsaw to make that 45 degrees cut out on the

trunnion beam, again, I am using parts of the red gum post. I quite enjoy using

hand tools, because I don't annoy the neighbours since the metal walls of my

workshop amplify sound.

Here is me using a handsaw to make that 45 degrees cut out on the

trunnion beam, again, I am using parts of the red gum post. I quite enjoy using

hand tools, because I don't annoy the neighbours since the metal walls of my

workshop amplify sound.

Here are the bottom and top blade guides made. Lucky there were one

to one drawings to reference off when making those complicated cuts. The knock

down screws are brass, because they only got have knock down screws in

my local hardware store. They were also M6, which is metric size, and the t-nut

and tap I bought were in imperial, so brass vs metal, the brass gave away.

Here are the bottom and top blade guides made. Lucky there were one

to one drawings to reference off when making those complicated cuts. The knock

down screws are brass, because they only got have knock down screws in

my local hardware store. They were also M6, which is metric size, and the t-nut

and tap I bought were in imperial, so brass vs metal, the brass gave away.

I don't quite trust how accurate I drilled in the end grain of the

trunnion beam, so I used some dowel markers to mark the exact position

of the corresponding dowels.

I don't quite trust how accurate I drilled in the end grain of the

trunnion beam, so I used some dowel markers to mark the exact position

of the corresponding dowels.

Homemade paddle switch, or dead man switch. My dad insisted that I

should either get one or make one, because of safety. He was also driven crazy

by the fact that I was using the band saw without any enclosures on to make the

trunnions. In the background, my glue bottle seems to be trying to steal the

spot light.

Homemade paddle switch, or dead man switch. My dad insisted that I

should either get one or make one, because of safety. He was also driven crazy

by the fact that I was using the band saw without any enclosures on to make the

trunnions. In the background, my glue bottle seems to be trying to steal the

spot light.

Homemade electric box, couldn't be bothered to go and buy one, plus,

I had to have a hole drilled on the side for the wire to come out. I later

painted it white.

Homemade electric box, couldn't be bothered to go and buy one, plus,

I had to have a hole drilled on the side for the wire to come out. I later

painted it white.

When everything was working and fitting

together, I took it all apart and did half a day of tedious sanding (lucky

human beings invented music), right up to 240 grit, which is the highest grit I

had. Then I loaded everything on a wheel barrow and transported it to the

dustless car garage.

When everything was working and fitting

together, I took it all apart and did half a day of tedious sanding (lucky

human beings invented music), right up to 240 grit, which is the highest grit I

had. Then I loaded everything on a wheel barrow and transported it to the

dustless car garage.

I painted all the enclosures with 3 coats of merbau deck oil, then

an extra coat of water based varnish to give it a bit of shine. The rest had 3

coats of water based varnish, except for the wheels, which had 5. The knobs

were painted black and had a coat of varnish, the electric boxes were painted

white. At the end, everything looked shiny and smooth.

I painted all the enclosures with 3 coats of merbau deck oil, then

an extra coat of water based varnish to give it a bit of shine. The rest had 3

coats of water based varnish, except for the wheels, which had 5. The knobs

were painted black and had a coat of varnish, the electric boxes were painted

white. At the end, everything looked shiny and smooth.

I noticed Steven was Chinese from the name in his email (为什么受伤的总是我啊), and asked about people building their own machines in China. Steven replied:

I used to live in China, but 2 years ago I moved to Australia and have since started woodworking. I also go to an English school to learn English. There is very limited space in China, and people don't usually do woodwork for fun, they do it for money. I don't know anyone in China who would build their own machinery either for fun or for money, but if I ever get to know someone in China who does, I will send pictures of his/her creation.

Steven