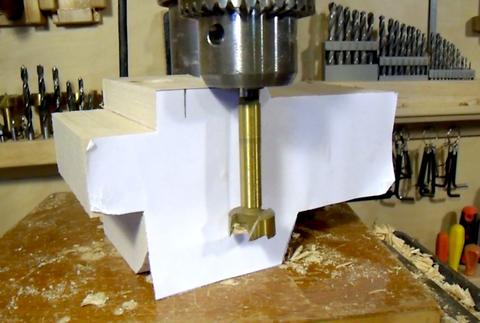

The top wheel mount consists of a single block of hardwood. The hole for the shaft,

or in my case, plumbing pipe, needs to be drilled all the way through. But my Forstner

bit is too short to drill it through from one side.

The top wheel mount consists of a single block of hardwood. The hole for the shaft,

or in my case, plumbing pipe, needs to be drilled all the way through. But my Forstner

bit is too short to drill it through from one side.

Conventional bandsaws all have a top wheel mount that consists of some sort of frame that

slides up and down, and some sort of tilt-able top shaft attached to that.

Conventional bandsaws all have a top wheel mount that consists of some sort of frame that

slides up and down, and some sort of tilt-able top shaft attached to that.

One of the experiments with this saw is to try to simplify this wheel mount to one block that moves up and down and tilts. The block slides between two parts sticking out of the top of the bandsaw frame

I'm exploiting the fact that the wheel, pulling down on the front, always wants to pull the block down and rotate it forward. So if I attach two pieces of wood to it as shown, that should be enough to keep it aligned.

The top wheel mount consists of a single block of hardwood. The hole for the shaft,

or in my case, plumbing pipe, needs to be drilled all the way through. But my Forstner

bit is too short to drill it through from one side.

The top wheel mount consists of a single block of hardwood. The hole for the shaft,

or in my case, plumbing pipe, needs to be drilled all the way through. But my Forstner

bit is too short to drill it through from one side.

My solution is to drill as far as possible from one side, and then use a long skinny drill

bit to drill all the way through. The Forstner bit has a slight point to it, so it's

easy to hit the center of the larger hole with the skinny bit.

After drilling the pilot hole all the way through,

I use it to guide the Forstner bit to line up the holes.

I'm always surprised at how well this works!

My solution is to drill as far as possible from one side, and then use a long skinny drill

bit to drill all the way through. The Forstner bit has a slight point to it, so it's

easy to hit the center of the larger hole with the skinny bit.

After drilling the pilot hole all the way through,

I use it to guide the Forstner bit to line up the holes.

I'm always surprised at how well this works!

After I made the block for the top wheel mount, I had an idea for an improvement. The block of wood

screwed to the front of the wheel mount cuts away a lot of the block right where it needs

to be the strongest. But if I let the wheel mount protrude into the frame a little,

it can push back against the frame and I won't need that block on the front.

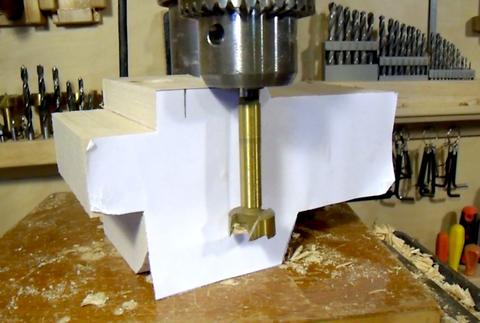

My finger is pointing at where the wheel mount (the

part with the faint diagonal lines) protrudes into the frame in my revised design.

After I made the block for the top wheel mount, I had an idea for an improvement. The block of wood

screwed to the front of the wheel mount cuts away a lot of the block right where it needs

to be the strongest. But if I let the wheel mount protrude into the frame a little,

it can push back against the frame and I won't need that block on the front.

My finger is pointing at where the wheel mount (the

part with the faint diagonal lines) protrudes into the frame in my revised design.

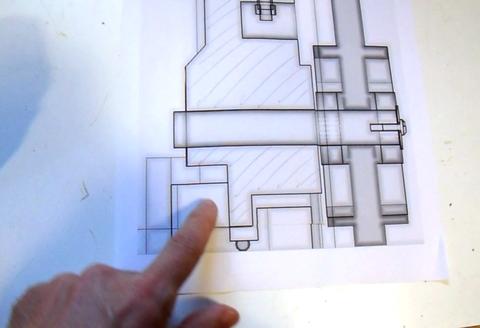

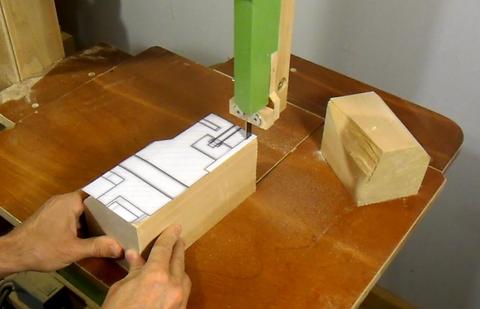

This design change necessitated cutting out a new wheel mount. Good thing I didn't have

to pay for these chunks of firewood that I use

for lumber!

This design change necessitated cutting out a new wheel mount. Good thing I didn't have

to pay for these chunks of firewood that I use

for lumber!

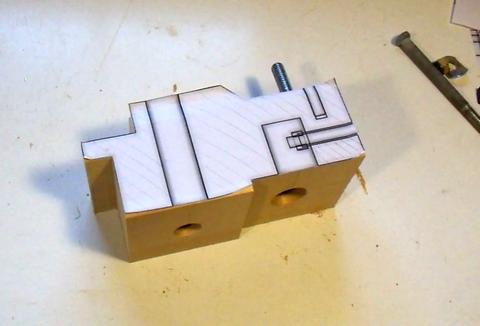

New wheel mount with the holes drilled in it.

New wheel mount with the holes drilled in it.

A screw from the top pulls it up, and another piece of threaded rod sticking out of the back will pull it back to adjust and keep the tilt.

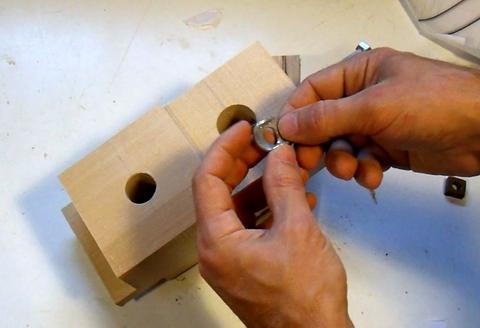

I bent a washer in the vise to go around the nut of the screw that pulls

up on the block. That washer helps to spread out the load, and keeps the nut

from turning as the screw is turned to adjust the tension.

I bent a washer in the vise to go around the nut of the screw that pulls

up on the block. That washer helps to spread out the load, and keeps the nut

from turning as the screw is turned to adjust the tension.

I used four strips of wood to act as "leaf springs" for the top tensioner, like

on my previous bandsaw. So far, I just have a wrench stuck on that bolt, but I'll

make a nicer handle for it eventually.

I used four strips of wood to act as "leaf springs" for the top tensioner, like

on my previous bandsaw. So far, I just have a wrench stuck on that bolt, but I'll

make a nicer handle for it eventually.

You can also see the strip of wood across the back, held on with the nut. The wheel tilt is adjusted by turning that nut, which in turn pulls the top of the block back more or less. It doesn't allow for large amounts of tilt but, in my experience, once everything is aligned and the tracking is adjusted, the top wheel always ends up dead on vertical anyway.

And here's the bottom wheel mount. Much simpler.

And here's the bottom wheel mount. Much simpler.

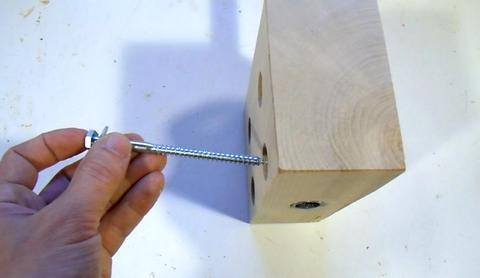

The wheel mount is bolted to the bottom of the frame with four 4" x 1/4" (100mm x 6 mm) screws.

The wheel mount is bolted to the bottom of the frame with four 4" x 1/4" (100mm x 6 mm) screws.

Checking that the bottom of the frame where the mount bolts on is square.

It needed some adjustment.

Checking that the bottom of the frame where the mount bolts on is square.

It needed some adjustment.

Using a hand plane to flatten the surface and make it square.

Using a hand plane to flatten the surface and make it square.

I don't have a shoulder plane, so I had to use a chisel at the edges.

I don't have a shoulder plane, so I had to use a chisel at the edges.

Also aligning the left to right angle of the bottom wheel mount

(that would be "yaw" in airplane terminology).

Also aligning the left to right angle of the bottom wheel mount

(that would be "yaw" in airplane terminology).

With everything lined up, I gave each screw a tap with a hammer to mark where the pilot

holes needed to be drilled.

With everything lined up, I gave each screw a tap with a hammer to mark where the pilot

holes needed to be drilled.

On my previous bandsaw I had a hard time drilling these holes because the bottom horizontal member of the frame was in the way. So this time around, I didn't glue those parts in until after drilling these holes!

With the wheel mounts more or less done, it's time to put on a blade and spin the wheels

manually to see how well it tracks.

With the wheel mounts more or less done, it's time to put on a blade and spin the wheels

manually to see how well it tracks.

![]() Looking along the wheels once everything was tweaked and the blade is tracking, they

are in line with each other, as well as the eye can see.

Looking along the wheels once everything was tweaked and the blade is tracking, they

are in line with each other, as well as the eye can see.

Next: Adding a motor